In the field of 3D technology, in addition to the speed and characteristics of the material when printing, the quality is also influenced by the "layer height". This parameter shows how high the next layer will be deposited.

For example, if the layer height is 0.1 mm, then 1 mm along the model height will contain 10 layers. There are 5 basic layer heights for FDM printing 0.05, 0.1, 0.15, 0.2 and 0.25 mm. In the case of photopolymer printing, the layer height can be up to 16 microns. Each layer height has its own pros and cons. One of the main ones is printing time, because the smaller the layer, the more time it takes to make a particular model. An important factor is the quality of the outer surface of the finished model, the larger the layer, the better these layers are visible, respectively, the surface is more rough. Also, the detailing of the finished product depends on the layer height, for spherical surfaces and small model elements, a small layer is the most suitable option. This also applies when your finished product will be used as a master model.

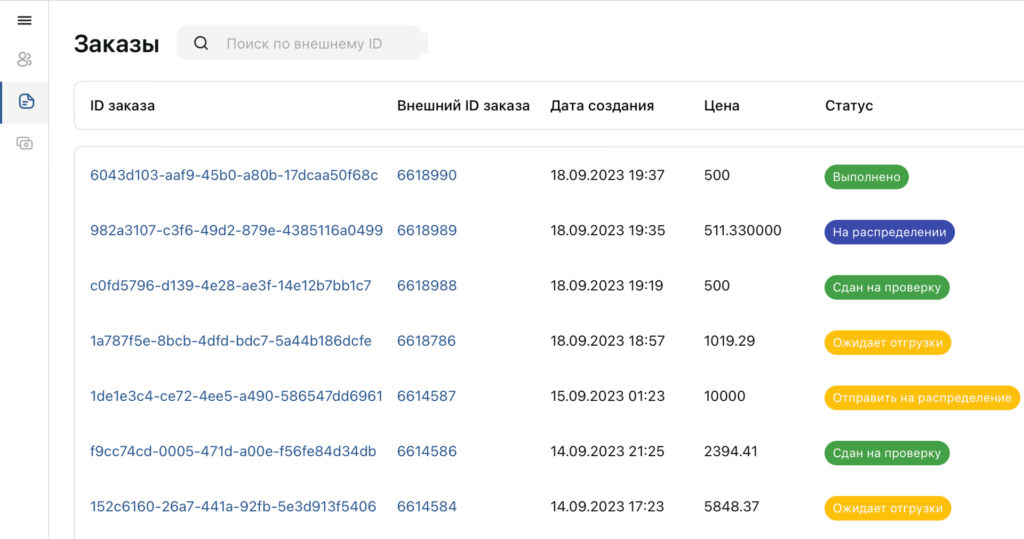

Below are photos of the same model, printed with different layer heights:

(0,25mm; 0,2mm; 0,15mm; 0,1mm; 0,05mm - from top to bottom)

Author: Studia3D. Ru

More articles from Studia3D. Ru