The term "Fill Percentage" is generally used in FDM (FFF) XNUMXD printing. How to choose the right type and percentage of Infill and what it can affect during further operation. How to reduce the cost of XNUMXD printing without harming the model.

The density of the interior of your part when XNUMXD printed is called infill. The ratio of the filled space to the total internal volume of your part is called the percentage of infill in XNUMXD printing. Infill in XNUMXD printing can be done in the following ways:

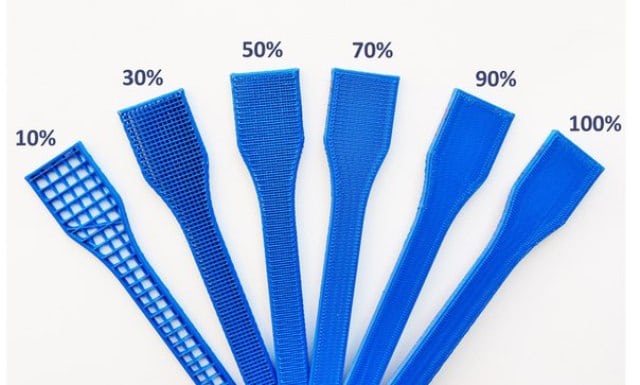

The percentage of Infill affects the strength with an increase in this parameter, and the lightness - with its decrease. As a rule, 50D printing is calculated based on the material spent on printing, taking into account support, therefore the cost of your part also depends on the percentage Infill. At the same time, it has been experimentally proven that printing with an infill of more than XNUMX% does not make any sense. The part from this does not become stronger. It is important to strike a balance between the cost and the mechanical parameters of your part.

But what really affects the mechanical parameters of printed products is the wall thickness. Set when preparing a part for printing. Sometimes with a minimum Infill, but with a solid wall thickness, the parts turned out to be stronger than with a large Infill and low thickness.

The Infill is automatically generated by the program.

An example shows how the Infill is generated in CURA.

Author: Studia3D. Ru

More articles from Studia3D. Ru