Dichloromethane was first synthesized back in 1839 by the French chemist Henri Victor Renaud, who obtained it using sunlight from chloromethane, acting on it with chlorine gas. In nature, dichloromethane is synthesized in the ocean by macroalgae, as well as in swamps and volcanoes.

In small quantities and at low concentrations, this is an absolutely harmless substance with a sweetish odor. With an increase in its permissible concentration in the air, dichloromethane becomes hazardous to health.

Safety first

Work with this solvent only in protective clothing, a respirator, goggles and gloves. It is a very highly volatile compound and must be handled in a well-ventilated area or with a powerful exhaust hood. The accumulation of this substance in a confined space can lead to an explosion.

However, it is a widely used solvent that is easy to manufacture and affordable. In 1993 alone, 400 thousand tons were produced in the USA, Europe and Japan. It is the main component of plastic welding glue. 3D modeling enthusiasts usually call him "D-Clos". When evaporated, this solvent forms silk threads and it is this property that is used when gluing plexiglass, polystyrene, polycarbonates, ABS polymers and polishing plastic models.

Harmful but necessary

"Diclo" is indispensable for degreasing the surface of glued plastic parts, it dissolves fat-containing substances and even fatty acids. The 3D figurine glue mix is quick and easy to prepare. It is enough to dissolve the pieces of plastic (from which the figure was printed) in dichloromethane, setting different density of the mixture in different bottles. A thick mixture is needed to cover deep cracks and joints of the figure. A more liquid consistency is used to process the figurine itself to smooth out wrinkles and layers, and a pure solvent evens out small irregularities in the figurine. Thus, a completely smooth surface of the model is obtained.

How to use it in 3D printing?

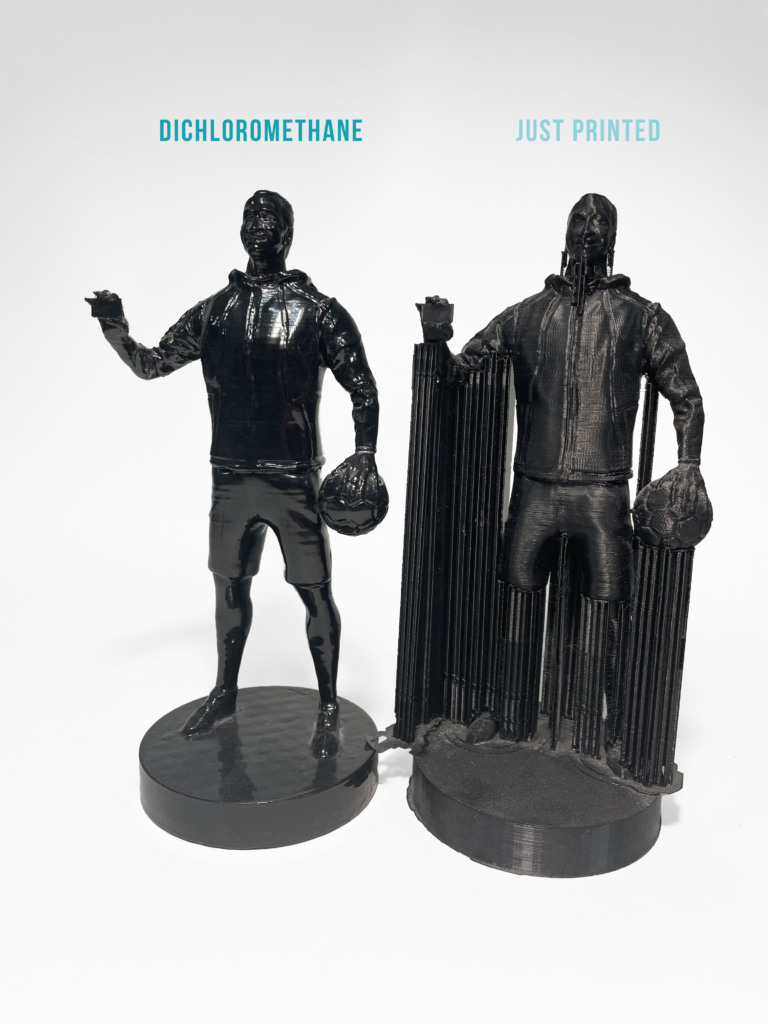

The easiest and most effective way to polish 3D models with dichloromethane is to immerse them in dichloromethane (or heated vapors of dichloromethane) for 1-5 seconds, and then free evaporation of the remaining solvent from the surface of the model for 1-2 minutes. The surface of the product becomes glossy (the so-called candy gloss). The same effect is obtained when the solvent is applied with a brush or cloth soaked in the solvent.

As a solvent, dichloromethane is very versatile. It is suitable for all types of plastics: ABS, PLA, HIPS and SBS.

Dichloromethane belongs to the 4th hazard class (unlike dichloroethane - a strong poison), that is, it is a low-hazard and safe chemical compound. It is also used in the food industry for processing exotic fruits, in the process of making tea and coffee, in brewing. Today it has found application in perfumery to create new fragrances of perfumes. It is even used in the production of ice cream, sweets, jams and drinks.

Attention!

But you must always remember that this is a very active chemical, extremely flammable and explosive! An overdose of it causes dizziness, headache, choking, loss of consciousness and even coma. With prolonged work with the substance, without observing precautions, you can earn cancer of the lungs, liver, and pancreas. People with heart muscle problems have abnormal heart attacks. Also, work with dichloromethane is contraindicated for people with problems of the nervous system, liver and skin diseases.

You should also not pour dichloromethane into the plumbing after use. It does not mix with water and can simply burn sewer pipes.

In general, it must be remembered that the permissible concentration of dichloromethane in the air should not exceed 50 mg / m3!

Be careful when working with this substance! Protect yourself and those around you!

Author: PR-service Studia3D

More articles from PR service Studia3D