3D printing formwork for casting inductor body

order 3d printing

Project for "Mosinductor"

The Mosinductor company deals with the solution of most industrial problems of induction heating. In particular, the company's specialists develop "turnkey" technological solutions for the manufacture of pipe bends, production of longitudinal welded pipes, heat treatment of parts for mechanical engineering and machine-tool building, melting of any metals and alloys.

Why 3D printing was chosen

For this project, it was necessary to make concrete formwork in the shortest possible time (10-15 days), keeping within the budget. Smelting a mold from metal is quite an expensive process, as well as creating a mold for casting from plastic. After evaluating the alternatives, it was decided to try 3D printing as the price-performance ratio was optimal.

Work process

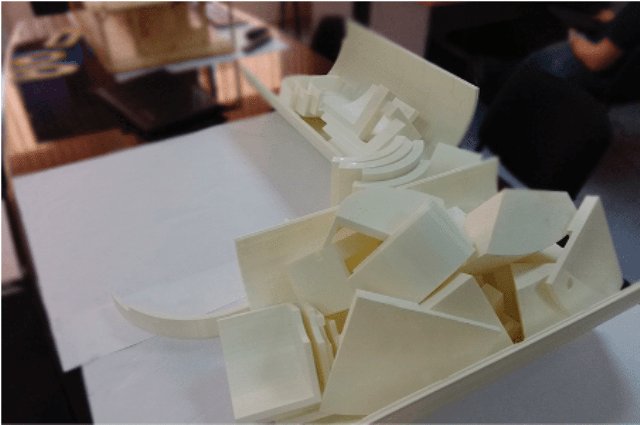

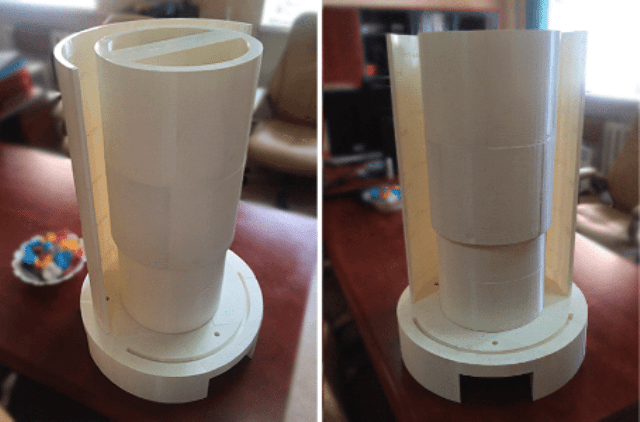

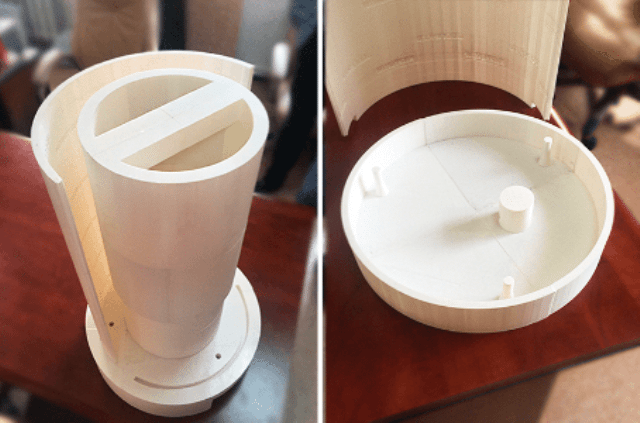

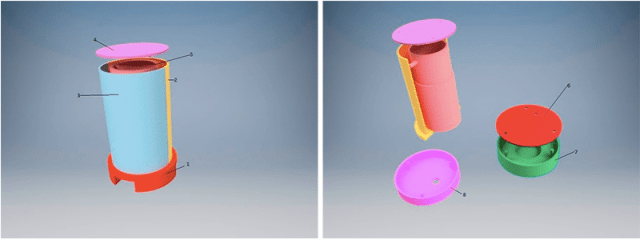

The manufacturing process began with modeling the shape according to the existing drawing. Three models were built, then they were finalized so that the structure became collapsible: a lock was added for the inner part of the formwork and a handle on top.

The form is made on printers: Prism PRO V2, Designer PRO 250 and PICASO 3D Designer.

Logos

On the inside of the form, the names of the companies Mosinduktor and Studia3D, which will remain after the part moves away from the concrete.

Printing took 4 days in total

Parts No. 2 and No. 3 were printed on an industrial printer, since they had to be monolithic and took up a fairly large space. The rest of the parts were cut and printed on Designer PRO 250 and PICASO 3D Designer. Part No. 1 was cut into 13 parts, part No. 5 into 16 parts. The rest (parts No. 4, No. 6, No. 7, No. 8) were cut into 4 parts.

Next - gluing and taping for accuracy, then - aligning the grooves. After the glue had dried, all deep seams were covered with a 3D pen and sanded (both with a sandpaper and a hand drill) to perfect condition. In total, post-processing took about 2-3 days.

- All Categories

- 3D models

- 3D printers

- 3D pens

- 3D scanners

- Studia3D Filament

- Studia3D Printers

- Studia3D Software

- Gadgets

- 3D Printer Granules

- Spare parts for 3D printers

- 3D Printer Products

- Tool

- Adhesive for 3D printers

- Materials for 3D printing

- Materials and prices for 3D printing

- Equipment

- Software

- Jobs

- Expendable materials

- Special offers

- Manufacturing technology

- 3D printing services Studia3D

- Photopolymer resin

- CNC processing

- Electronics and components

Studia3D Viewer

Get 5% discount on an order from the app

The app allows you to view 3D models, mesh specifications and place an order for 3D printing on the go!

To learn more "