3D printing of Art objects for the chocolatier

The world of art objects

Samples of art objects today can be seen everywhere - in exhibition centers, on the streets, in restaurants and cafes. Art objects are a work of contemporary art that is unlike anything else. And this contemporary art goes hand in hand with modern technology. Such as, for example, 3D printing. After all, both of these directions make us look at our world and our own possibilities in a new way.

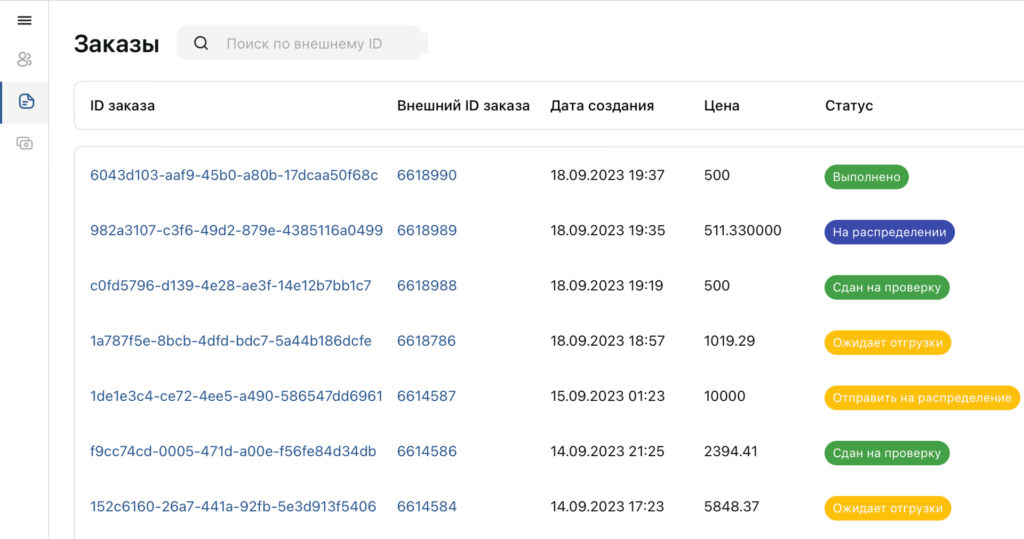

The company "Studia3D» has been working in this area for several years. One of our recent customers of art objects is the Moscow restaurant Wabi Sabi not far from the Barrikadnaya metro station, owned by the Shokoladnitsa group of companies.

Start of work

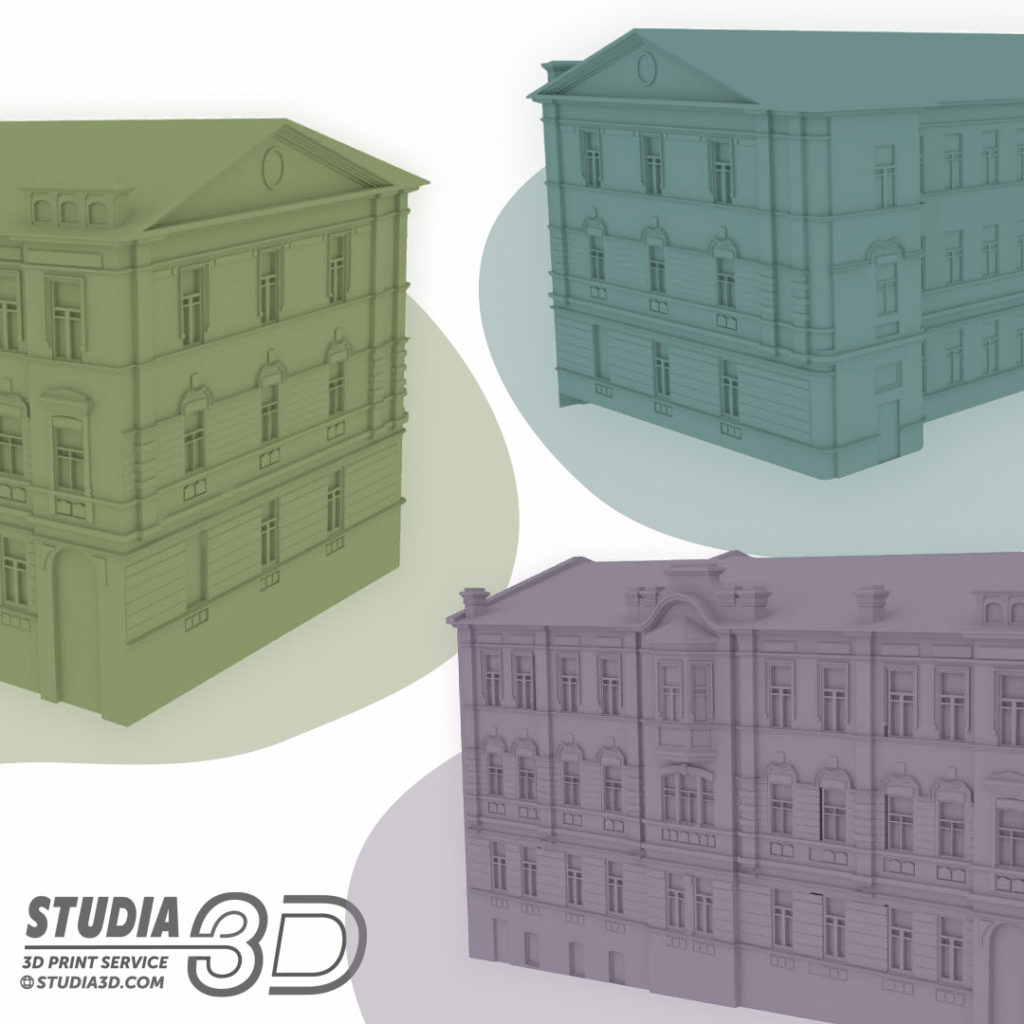

The customer provided us with 3-dimensional models of the desired objects. Since they did not meet the requirements for XNUMXD printing, our employees developed new ones based on the files provided by the customer.

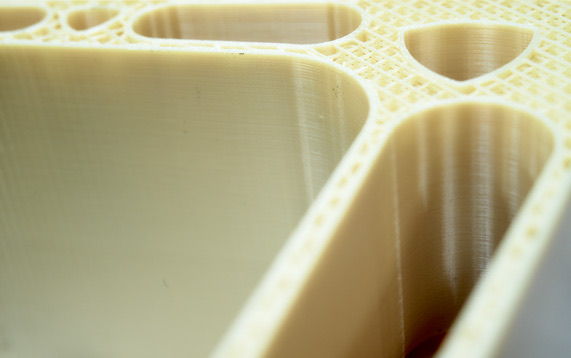

Prototyping

Before proceeding with the production of life-size art objects, we made their reduced copies so that the customer could be convinced of their compliance with the stated requirements.

The birds passed the size restrictions and went to print. The decision on dolls of such a large size remained with the chief technologist.

Segmentation of the model

Our specialist “cut”, “dissected” the digital model into many segments so that each of them has the necessary physical parameters suitable for work on different types of 3D printers. After this electronic dissection, we received files ready for 3D printing. It took 3 days to XNUMXD print the order.

Preparation for painting

The time has come for the process of gluing the multi-colored parts into a single whole, although in fact, we do not use glue. Our technology uses a special chemical solution that allows the parts of the product to be soldered, and this method gives the finished product a large margin of safety.

Paint shop

The last stage of work took place in our paint shop: putty, smoking, priming, elimination of minor defects and, finally, finishing - polishing and coating of the finished sample with auto enamel with a protective varnish resistant to scratches. This is a bright varnished dot in our technological chain.

Putty

Primer

Coating

Almost done!

Good product stability was one of the customer's requirements. We achieved this by shifting the center of gravity of the art object closer to the floor. For this, liquid silicone was poured into its lower part. Everything is very simple and effective.

The entire cycle from the moment of ordering to the delivery of the finished product took only 3 weeks, and without the use of technologies like ours, no one does such things in such a short time. And one more pleasant and important bonus for the client: we carried out delivery, installation and installation at our own expense. Turnkey art objects!