There are a huge number of traditional manufacturing processes: milling, turning, welding, forming and others. Most of them work on the principle of either changing the shape of the product, or cutting off excess material when forming the final shape of the product. A distinctive feature of 3D printing is the process of forming a product - a method of adding material. Since this method is very different from traditional types of production processes, then the process of creating a design, designing a product, differs radically.

What is the reason for this approach? Of course, with the manufacturability and flexibility of 3D printing, since we have to take into account fewer variables when designing. For example, the shape of the product during casting limits the need to remove the finished product from the mold. And if we do not provide for the correct angles on the side parts of the model, then we run the risk of missing the molded product from the mold altogether. And incorrect analysis of penetration add pore problems inside the molded product, resulting in rejects. In the case of milling, we always have to deal with the excess weight of the product. We cut off excess material from the workpiece, and the more you need to cut, the more the machine works (the more expensive is the part). The more we try to save (reduce the operating time of the machine), the heavier the part becomes. There are a lot of such examples.

Of course, 3D printing, as well as any other technology, has its limitations. However, there are fewer of them, which makes it possible to manufacture products of a more complex, and, as a consequence, the most interesting shape. We do not have a form from which to get the part, we have no problems with weight, since the less weight, the less the machine works. Understanding this, you gain serious power in design, and then in the final characteristics of the product. In some cases, this allows for the most cost-effective process compared to alternatives. If these two factors coincide, then 3D printing becomes an integral part of the manufacturing process.

The stages of the production process themselves are not very different from the alternative ones.

3D scanning. Produced by Artec Eva 3D scanner.

Creation of a sketch project in the 3Ds Max program. According to these sketches, a prototype made of cardboard was assembled and worked out.

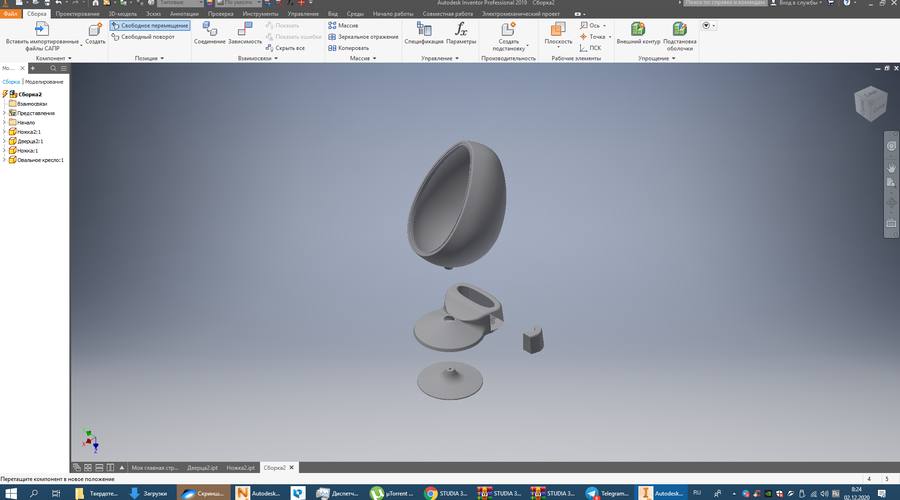

After all the necessary measurements, we proceeded to CAD design.

The entire assembly was tested programmatically.

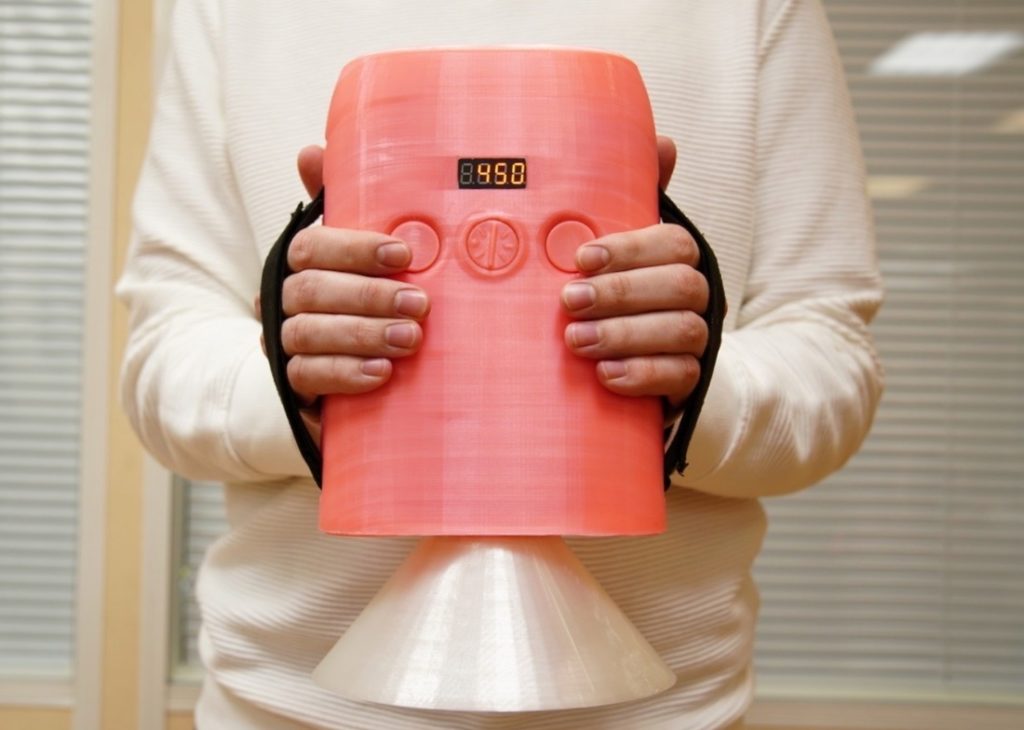

Then we started 3D printing. Printing was performed in segments with subsequent soldering of parts.

After covering with film and assembling, the result surpassed all expectations!

There were various colors. We liked blue the most.

We are ready to solve your problems on 3D modeling.

A short video of the assembly after design.

Author: Studia3D aggregator

More articles from Studia3D aggregator