One of the most frequently asked questions when working with clients is: "What is 3D printing support?" In this section, we will clearly show what it is customary to call supports and what types of supports exist at a given time.

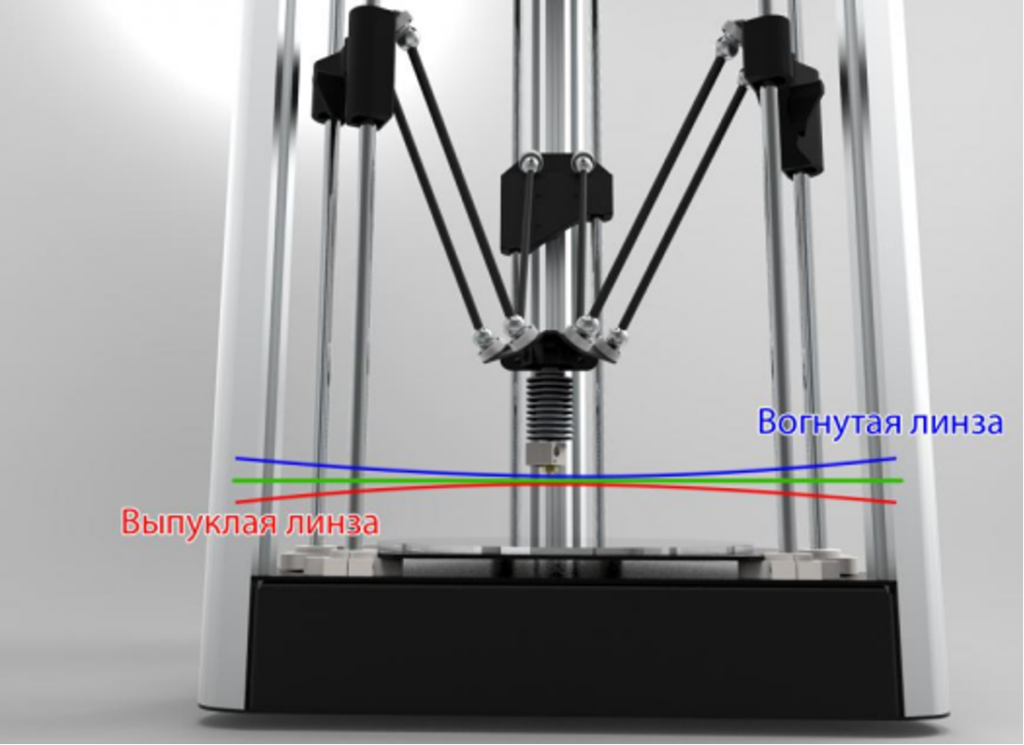

Support material - an auxiliary material used in 3D printing to build complex objects and increase the quality and stability of construction. Without the use of support, it is impossible to XNUMXD print models with cavities, overhanging structures, complex detailing, thin walls or floors, and other complex elements.

Simply put, support serves as a kind of temporary foundation for the printed product. Layering assumes that each next layer of the product is based on the previous one. In the case when a support is not provided under the first layer in one place or another by the product design, support comes into play.

It must be understood that the removal of supporting structures is one of the most difficult types of work.

Therefore, this article was written, fully explaining what support structures are and why they are needed in 3D printing.

How to determine where support is needed?

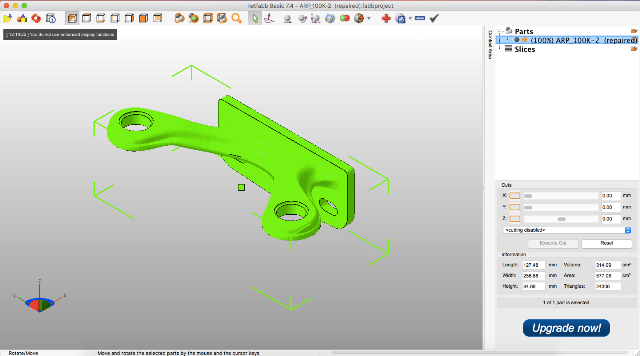

This is automatically done by the software that comes with all professional 3D printers. You just need to upload the file in STL format, and the program will independently calculate where for a high-quality construction you need to use auxiliary material. It is worth noting that most software also allows the user to edit the number and location of auxiliary structures. The software is directly related to the capabilities of a three-dimensional printer and will automatically show you where support is needed and where not.

In addition, the program calculates the amount of required auxiliary material before printing.

If we do not agree with the automatic calculation of supports by software for a three-dimensional printer, then software comes to the rescue, where supports can be placed manually. The picture shows an example of manual construction of supports in the AutoDesk MeshMixer program.

Types of support materials

Soluble

There are 2 kinds of soluble auxiliary materials such as HIPS and PVA. These types of plastics are used for printing supports in complex models, where the high quality of the resulting product is an important component.

Each type of plastic has its own pros and cons.

So, for example, HIPS can be used both as a main material and as an auxiliary one. This plastic is soluble in limonene, therefore it is excellent for printing supports, where the main plastic is ABS, since they do not interact with each other. It also has its drawbacks - it is the high cost of limonene.

On the contrary, PVA is used exclusively as an auxiliary material. It dissolves well in water and is only compatible with plastics where PLA is the main material. But there are two important differences from HIPS: the high cost of the material and the more simplified post-processing of the finished product.

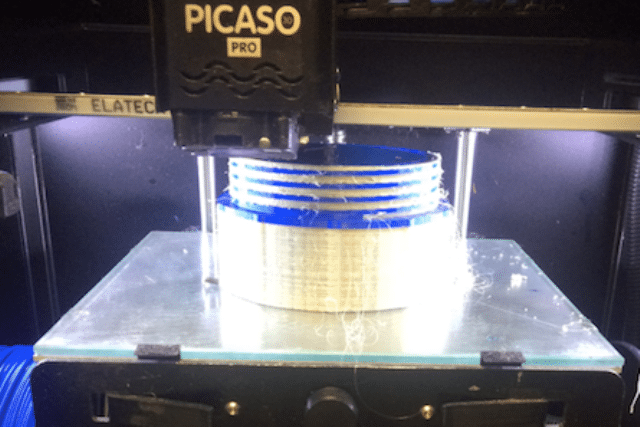

3D printer in the process of printing with supporting structures.

The finished product immediately after 3D printing.

Detail after washing out the supporting structures.

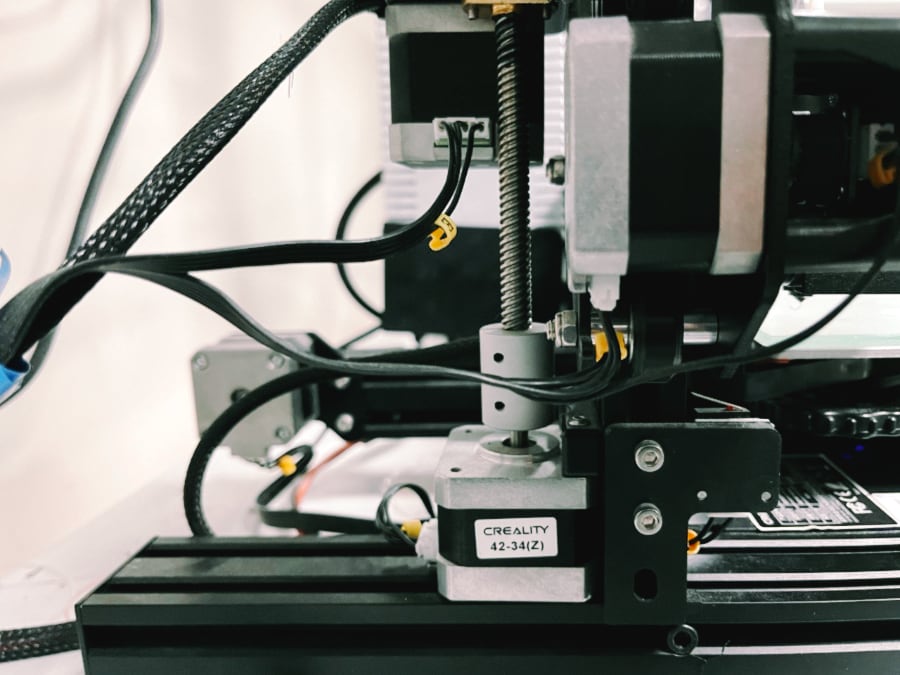

Mechanically removable

Excess material is broken off, sawn off, cleaned off. In this case, the same material from which the model itself is built acts as a support. But in order to facilitate its subsequent removal and reduce the consumption of the model material, the support is built more “sparsely” in comparison with the object itself. It has a much lower density and strength, sufficient only to temporarily withstand the weight of the grown object.

Lost wax

Melts and flows out with slight heating (much lower than the deformation temperature of the main product). Usually has a wax base. Advantages: delicacy, precision of application. Used in photopolymer and wax 3D printers of the ProJet series from 3D Systems.

Powder support

Powder 3D printing technologies should be mentioned separately. Here, the same material acts as auxiliary and main. However, that part of the powder that was "auxiliary" can be reused after cleaning as the main material. Thanks to this, such technologies are practically waste-free. The only exception to the rule is XNUMXD metal printing. When printing with metal, the shrinkage of the metal must be taken into account. In order to prevent your part from twisting and distorting during the printing process, it is necessary to secure it with supports.

Author: Studia3D. Ru

More articles from Studia3D. Ru