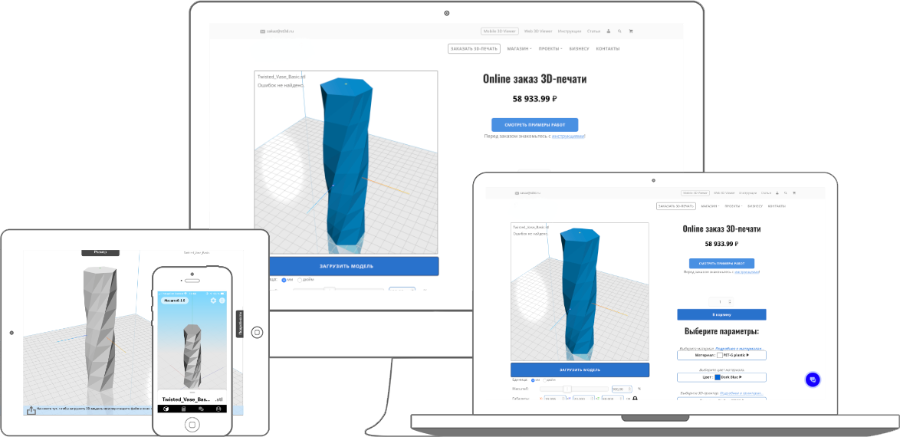

In our automatic settlement system cost and ordering for 3D printing of models appeared polypropylene PP + - plastic with improved technical properties. Let's dwell on it in more detail.

Disadvantages of classic polypropylene (PP)

The main problem that arises in the process of 3D printing using FDM technology is material shrinkage. Polypropylene (PP) can behave unpredictably when exposed to high temperatures, which will affect the quality of the finished product. That is why the material is referred to as "complex". In addition to heat shrinkage, polypropylene remains vulnerable to direct sunlight, oxygen, and loses its elasticity at temperatures below minus 15 ° C (shock resistance decreases in proportion to a decrease in temperature). At the same time, the material has a number of advantages, on the basis of which they developed an improved version of polypropylene for 3D printing - PP +.

Advanced 3D printing material

Polypropylene PP + is a chemically modified version that features low heat shrinkage. The material retains the advantages of the original filament and is practically devoid of its disadvantages. PP + can be used to print products with a large margin of safety, since it has high interlayer adhesion (the layers adhere well to each other).

Material properties are retained even when the model is 100% filled. There is no shrinkage, which makes it possible to manufacture products with precise parameters without distortion.

Features of PP + material

- Low coefficient of heat shrinkage

- High resistance to mechanical stress (abrasion)

- Softening point over 95 ° C

- Operating temperature: from -10 ° С to + 80 ° С

- Elasticity

- impermeability

- Resistance to the effects of reagents (acids, alkalis, mineral and organic oils, alcohols, gasoline, acetone)

- Recyclable

- Non-toxic

What is it for?

Polypropylene PP + is used in the medical and food industries. Various products are made from it, including consumer goods.

You can get more information on PP + material and order 3D printing from our experts.

Author: PR-service Studia3D

More articles from PR service Studia3D