By Mikhail Scheglov, inventor:

I started developing a unique rescue module in the spring of 2014. This project is part of a study on modeling pneumatic structures capable of collecting, storing, distributing, and even converting solar and precipitation (rainwater) energy. Before the rescue module, at the beginning of 2013, I developed and patented a greenhouse module.

After researching the state of the environment, the idea was born: to create a studio for modeling protection systems and developing various structures. There are also several directions for the design of underground residential buildings, above-water residential systems, international development environmental centers and other projects.

The depth of implementation of projects is different and depends only on the creative efforts and abilities of its participants. The geography of cooperation in the development of projects already covers such countries as Spain, Bulgaria, Germany and China. In Russia, the main points of development are still Moscow and St. Petersburg. Federal agencies are showing interest in the developments, and participation in large innovative exhibitions, for example, INTERPOLITECH-2015, is proposed.

About the rescue module project

In the assembled ("transport") state, the rescue module is in the capsule, and to bring it into working condition, it is only necessary to open the valve of the cylinder with a compressed gas mixture located in the lower part of the capsule. The weight of the capsule with the module inside is no more than 50 kg and can be significantly reduced by using modern nano-materials. The transition time of the module from the "transport" state to the working state takes several minutes, after which people have the opportunity to place themselves inside the module and along the outer perimeter on the expansion elements of the base.

At the same time, the buoyancy of the rescue module can accommodate up to 18 adults outside and up to 12 people inside with an average weight of 80 kg. The capsule has a rigid body that allows it to be dropped onto the water surface from a height of up to 50 meters. Under the influence of pressure, the rescue module is pushed out of the capsule by the piston, filled with air and takes on a "working" form. Outside the module there are "ears" with holes-rings for tying the module to trees, houses, poles and any structures that are stable during a flood.

You can tie ropes with anchors to the lower rings, which allow you to fix the module in a strong current. This is especially true in case of flash floods and a sharp rise in water. A rope loop is also passed through the lower rings, which you can hold onto and which helps to get inside the module.

The design of the rescue module allows for the collection and storage of rainwater. The collection of water is provided by the dome, which is initially a funnel-shaped roof with a lower point in the center of the module. Water enters the capsule through a through hole in the telescopic rod and piston. The limiting handles control the Infill of the capsule: as soon as the capsule rests with the handles on the central float, the piston, under the influence of the water entering the capsule, begins to lift the module dome with the help of the rod, moving the roof from the funnel-shaped position to the conical one. Rainwater harvesting stops automatically. Thus, the module autonomously collects rainwater and stops this process. The volume of collected water is about 100 liters.

The collected water can be used for domestic needs. Filters for water purification are included with the rescue module, which allows it to be used for drinking. Access to the water collected in the capsule is provided by plug segments screwed into the piston body.

Ventilation is carried out through the passageways, which are equipped with hermetically fastened curtains. Each entrance is provided with two curtains, which provide thermal insulation of the interior of the rescue module. The dome of the module has transparent segments to allow daylight to pass through. In the corners of the inner walls, in waterproof pockets, there are rescue supplies: a first-aid kit, long-term storage food kits, a mobile phone with solar-powered batteries, lighting lanterns, warm clothes, and blankets.

During floods and especially with a sharp rise in water, the current carries a lot of debris, trees and various debris that can damage the material of the inflatable elements of the module. To protect against pressure loss, the design provides for the division of the gas mixture supply into six independent circuits. Each circuit provides Infill of one element of the module base, one wall element, one mattress and 1/6 of the volume of the central float. All structural elements filled with a gas mixture are equipped with valves. Such a system of protection against destruction makes it possible to localize the depressurization of the inflatable elements of the rescue module.

If the expansion elements of the module base are damaged, the structure of the rescue module will retain its stability in the water, only losing part of its buoyancy. Loss of buoyancy will require a proportional reduction in load and limitation of the number of people on the rescue module.

Process of creation

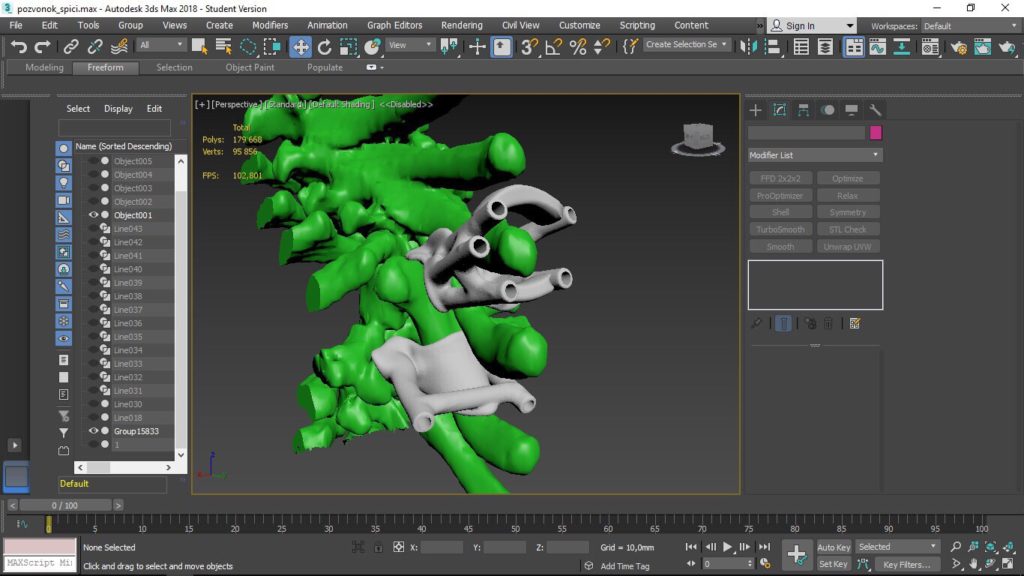

Pneumatic structures have a great future, they will open up new opportunities for humanity in the development of spaces, maintaining the balance of the environment not only on land, water surface or in the depths of the sea, but also organizing settlements on other planets. We had a specific task: to deliver an effective presentation. As a result, it was decided to make a booklet with a detailed description of the project and illustrations, a video description of the project and a large-scale collapsible color model on a 3D printer.

I am sure that models of pneumatic structures and their parts made on a 3D printer are an integral part of both the presentation process and work on the design of prototypes in production. This shows my experience with Chinese engineers. Without a volumetric model, the time to work on a structure increases significantly, travel costs increase and the quality of the future structure decreases.

Since we don't have our own printer yet, we decided to use the services of a print studio. The preparation of the files was done by my project partner, it took about two weeks. Sorrows model in the company Studia3D.ru.After a little experimenting with the material for printing, it was decided to stop at PLA plastic. The first model of the rescue module was made for about one week and cost us 11 thousand rubles with all the modifications.

Undoubtedly, a 3D printer with its capabilities for creating three-dimensional models of various designs has thoroughly entered my life. Models of pneumatic structures significantly expand the possibilities of presentation and evaluation of the project, both by customers and potential consumers.

Author: Studia3D. Ru

More articles from Studia3D. Ru