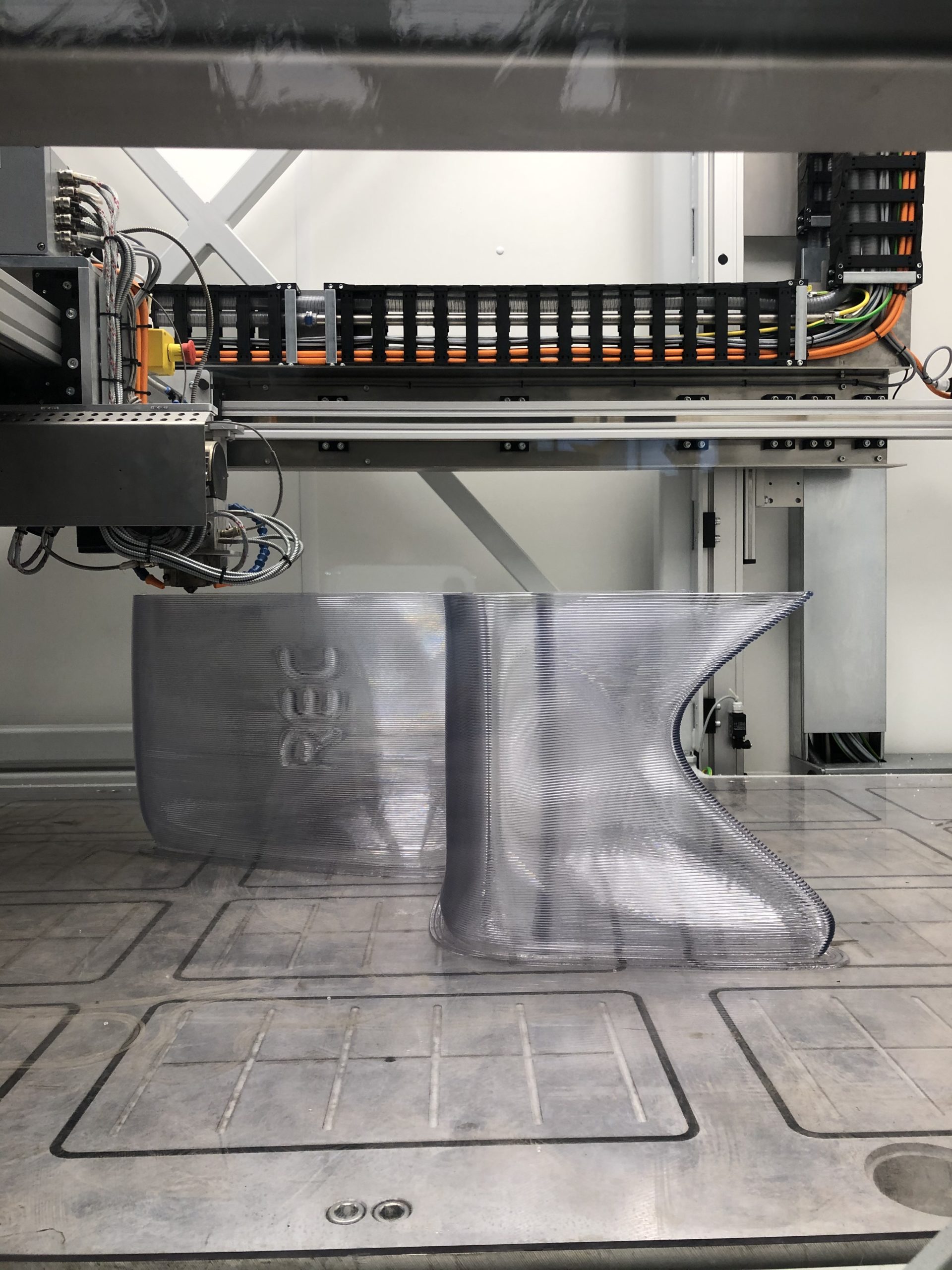

FGF (Fused Granular Fabrication)

A 3D printing method that uses granular plastic as raw material. It was developed in the 1990s and is one of the most accessible and widely used 3D printing methods. The essence of the technology lies in the fact that granular plastic is heated to a melting point, after which it is extruded into the desired shape using a special nozzle-extruder.

Also, it is important to note that the use of granulated plastic in the FGF method makes it more affordable and economical. In addition, this method allows you to create objects of large sizes, which expands the possibilities in production. The FGF method has found its way into various fields, including medicine, aviation, architecture, and even toy production. Due to its simplicity and efficiency, the FGF method is becoming more and more popular and in demand in the world of modern technologies.

.

Accuracy

Limit deviations:

± 4 mm (dimension up to 200 mm per side)

Surface Roughness:

Strong cost

Minimum thickness

Wall thickness:

not less than 4 mm

Shell thickness:

not less than 4.2 mm

Minimum opening

Minimum opening:

5 mm

Hole without support:

5 mm

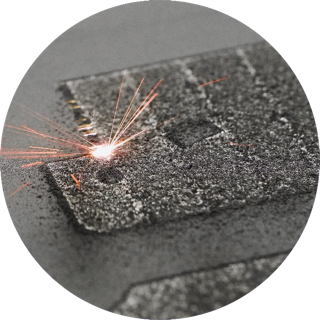

Other technologies

ORDER 3D PRINT FROM SMARTPHONE!

Get a 5% discount on your order through the app.

We will make the product as soon as possible!