The general trend towards sustainable development and reasonable consumption made the participants in the additive sector think about the prospects for the development of their own industries.

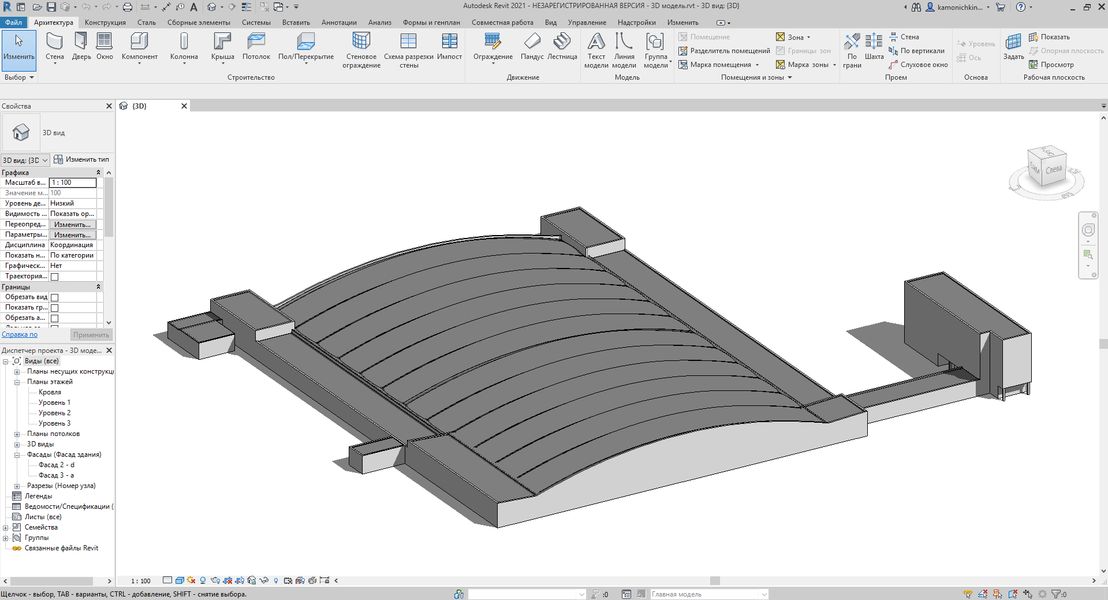

The Belgian brand Colossus has already taken the first step in this direction. Experts presented to the market large 3D printerprinting with recycled materials in the form of granules.

That is why we are carrying out the third step together with REC. As you might have guessed, we create pellet materials of domestic production. We have a long fruitful work ahead of us, but the final product solves several problems at once:

That is why we are carrying out the third step together with REC. As you might have guessed, we create pellet materials of domestic production. We have a long fruitful work ahead of us, but the final product solves several problems at once:

- Reduce the cost of consumables

- Increase the environmental friendliness of production

- Ensure the economic security of domestic industries

- Simplify the logistics of supplying consumables

Together with REC, we are changing the vector of development of additive manufacturing and ushering in the era of engineering leadership over technology for the benefit of people.

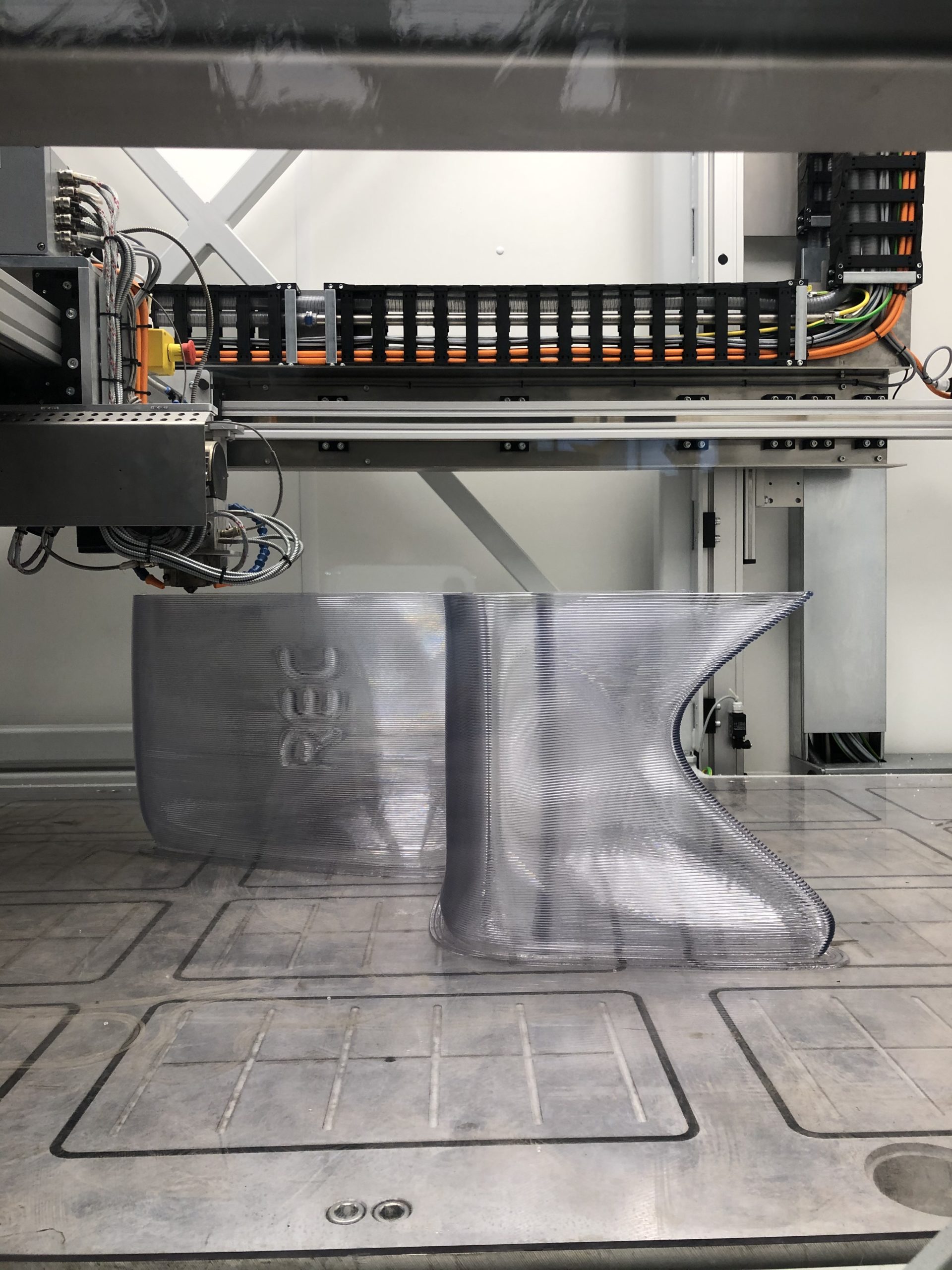

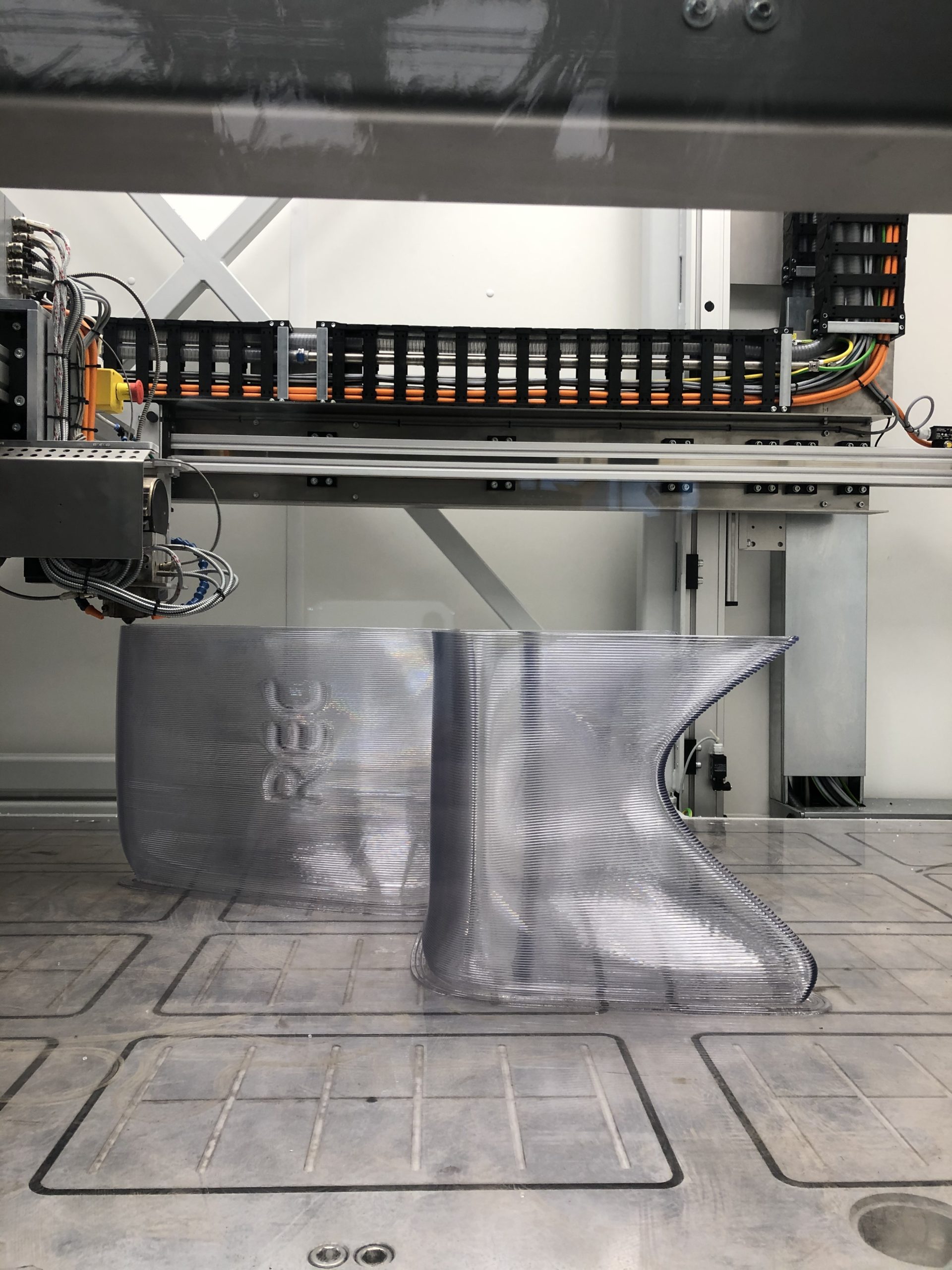

Just look at this quality!

Our partners REC

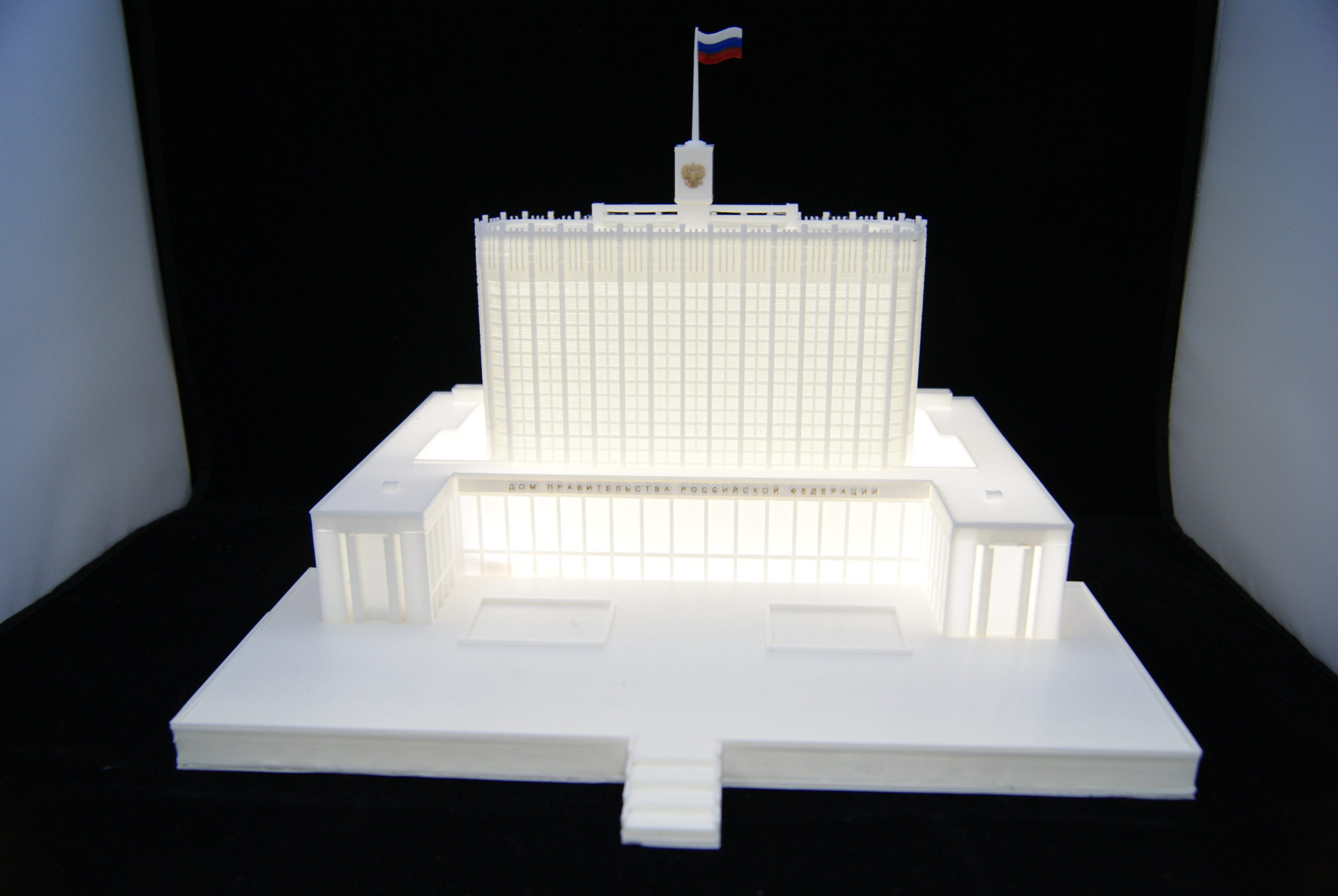

The results were not long in coming!

We did not postpone this business indefinitely and for 3 days tested REC options and selected technological modes for large-sized printing with granular material.

⠀

The gallery shows the results of our work with PET-G from REC on the Colossus 3D printer. ⠀

The test results were recognized by our specialists as successful, so we have already started fulInfill orders along a completely new technological path for the Russian market!

We decided to pick up the first batch of granular material in person and visited our partners. REC production fully complies with European standards. Granules for 3D printers will appear in our online store soon.

Author: Ad

More articles from ad