I got acquainted with this machine for a long time, but for a long time I could not get myself together in order to write this post. Couldn't find a balance or something. Obviously, I lacked the enthusiasm to combine the two opposites at one extreme. You see, I've been doing 3D printing for a very long time. During this time, 3D printers, like machines, like machines, like robots, have become for me a little more than just engineering devices that allow me to solve problems of a wide profile. Therefore, I will compare this 3D printer with something nameless and inanimate. Today we will philosophize a little. Otherwise, I simply won't be able to reveal the full meaning of the title of this post. What is the first thing that pops up in people's minds when they hear the phrase "not like everyone else"? Just like that, without any clarifications. Like a black spot on a white background? Or like a clear diamond in a pile of stones? There is a feeling of contradiction, isn't it? On the one hand, there is a feeling of admiration, on the other, a feeling of sadness and sympathy. And so in everything, regardless of what objects fall under the description, animate or not. If "not like everyone else," then either better or worse than everything else. The same contradictions arose in me when I got to know this Swedish car better.

First, let's take a look at what makes this 3D printer different from others. This is metal for you guys, not plastic! But the point is not about the material of the finished product, but about the material of the supporting structures! In plastic, for example, they came up with the idea of replacing the support material with one that is soluble in water or acid. What about metal? Removing support structures is a cornerstone in metal design. That is, in fact, we have a 3D printer, but we cannot print, because we cannot remove the supporting material inside. This 3D printer won't have such problems. I print what I want. Without any restrictions! And this, my dear readers, allows the user to create without restrictions !!!

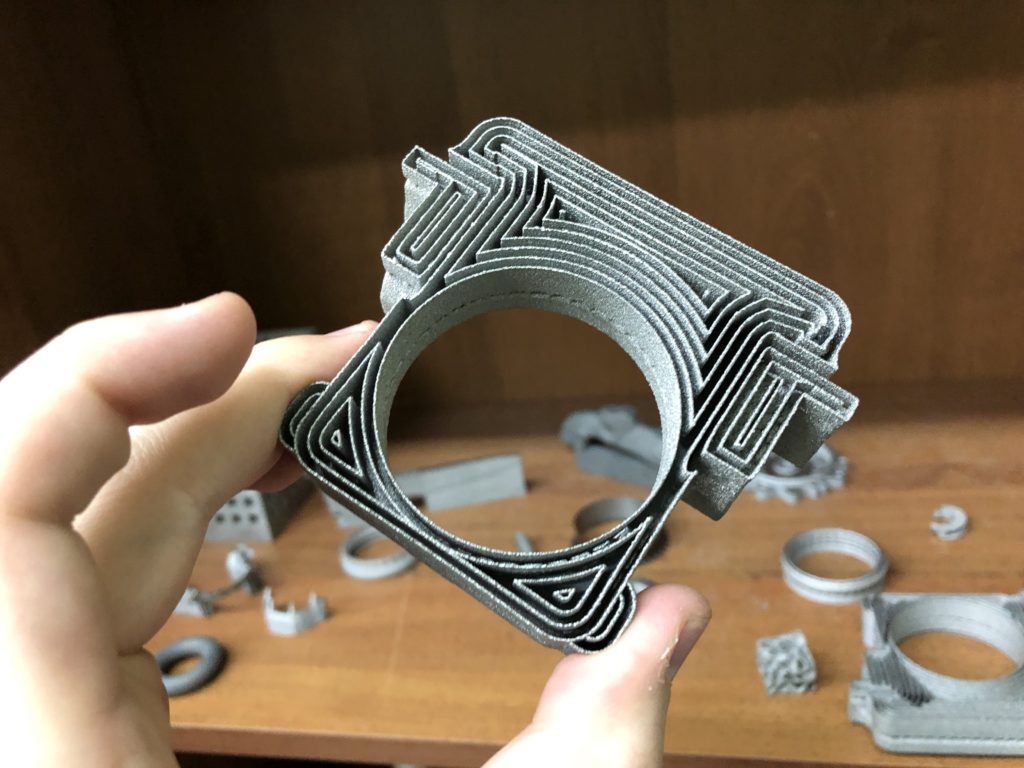

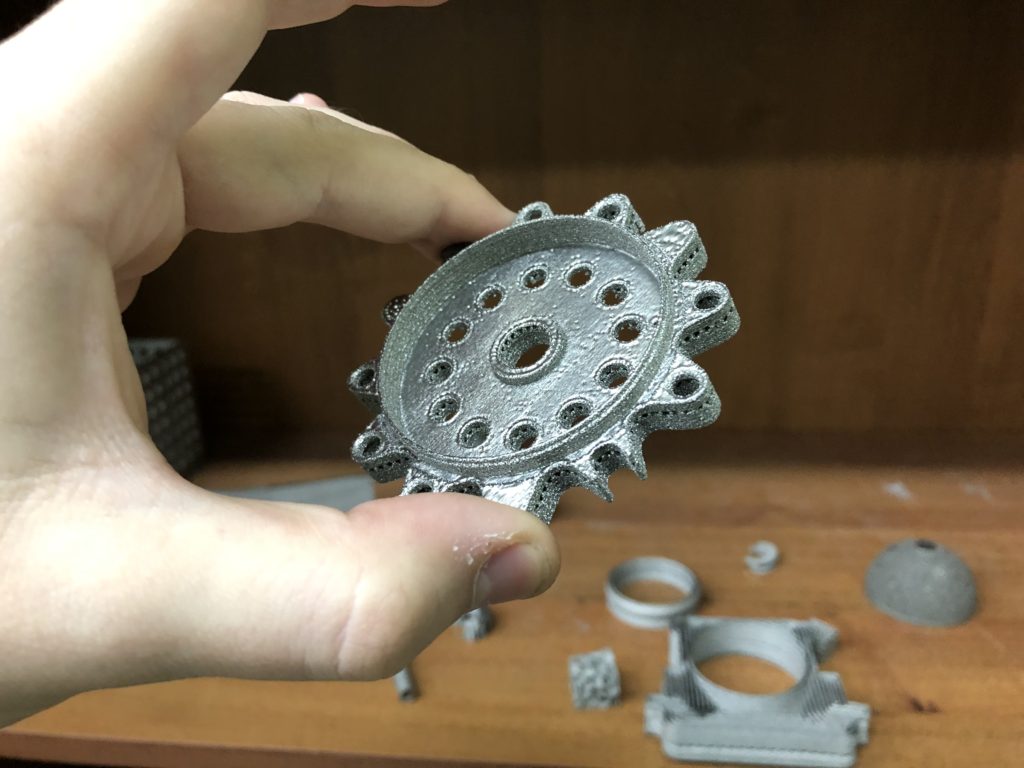

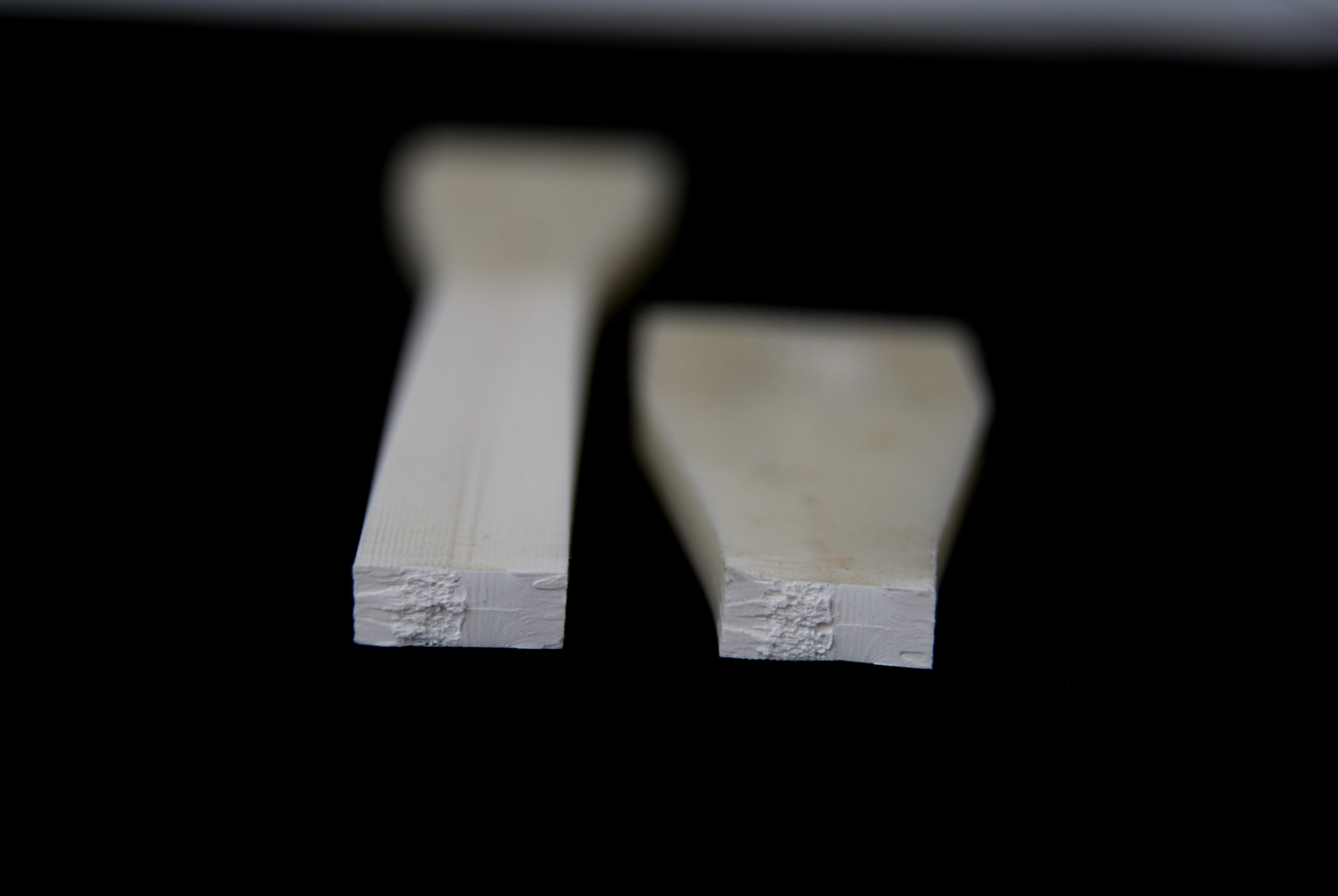

As an example, below is a photo of an example of printing with cobalt-chrome on a 3Dsystems 3D printer. Well try to remove support =)

How is this possible?

Here's how: An electron beam controlled by electromagnetic coils is used to sinter metal, providing an extremely fast and accurate beam under the control of specialized software that allows the metal to be melted selectively. The use of an electron beam in conjunction with non-conductive metals eliminates the need for a supporting material.

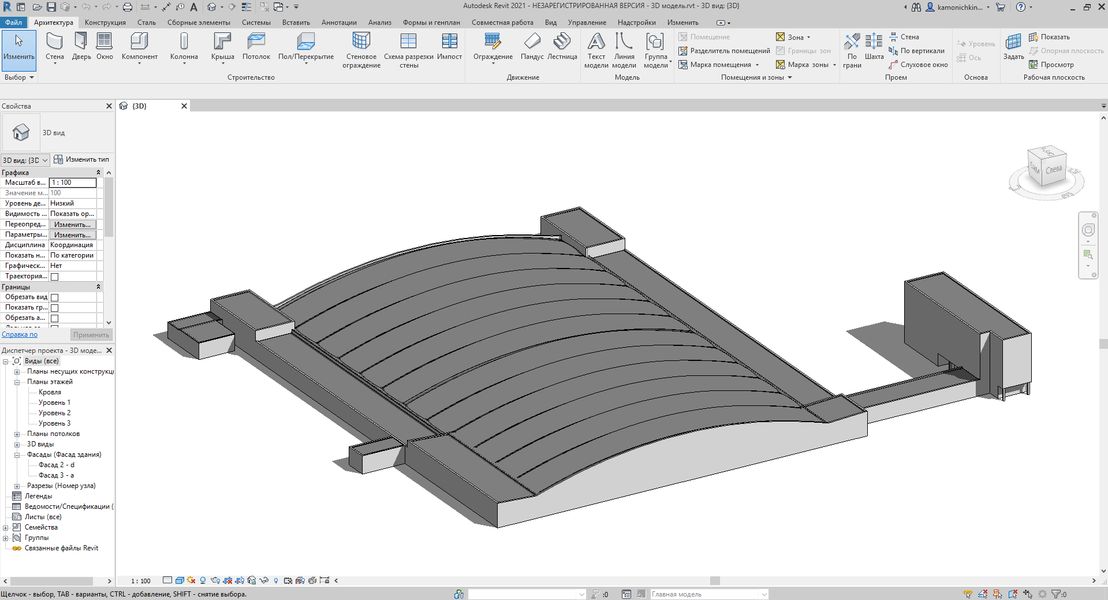

Principle of operation:

What materials does the machine work with:

Extended description of ArCam printers [Eng]

Extended description of materials [Eng]

The quality of the products. No surface quality studies have been carried out, but a good visual result is obtained. Certainly not better than analogs, but due to the support, he can be forgiven for everything. More than enough for the backlog before shot blasting.

This is just something incredible!

Whoever did it and ate it.

Do you know why these 3D printers are still not widespread? GE bought the technology together with the manufacturer. And after a while, having tested the technology and improved the car, I completely forgot to collect cars for sale. For internal use only. Like any diamond that the finder will take for himself, removing this gem away from a pile of other useless stones and hiding it deep behind the collar so that it will further benefit the owner personally. And after thinking for a while, I came to the conclusion that it is absolutely unimportant how others will relate to this diamond, whether it lies dead weight in a dark safe, or flaunts in the cut of a ring on a woman's hand, or is completely part of a precise instrument, something else is important. ! It is important to understand that whether a diamond will be an outcast or unique depends less on the diamond itself. So it is with any object, including our printer. The further fate of the 3D printer, as a technology, will depend on General Electric.

Why does General Electric need this?

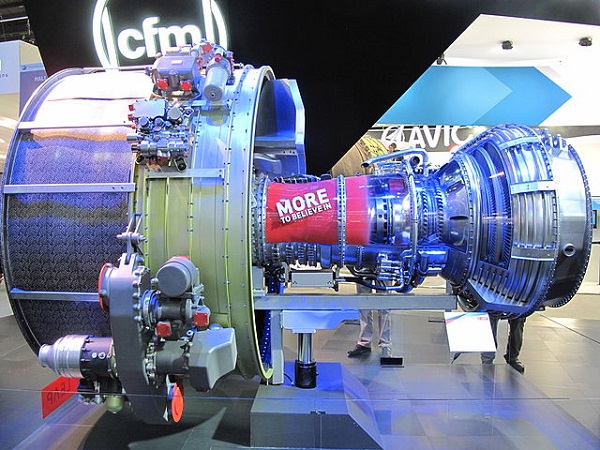

In order to print make parts for aviation. Yes, yes, it is 3D printing for aviation. What kind of products does GE make on its 3D printers? And here's an example. Fuel injectors for turbojet engines.

Few people know (including myself until recently) that General Electric, among other things, is engaged in the production of aircraft engines. And with the use of 3D printing technologies, it has replenished its portfolio of orders in the amount of $ 31 billion!

Well, what does 3D printing have to do with it? The fact is that this includes 1658 new generation LEAP engines with the same 3D-printed nozzles, 19 nozzles for each engine. In total, the corporation has received orders for about fourteen thousand engines with a total value of $ 27,3 billion, so that every eighth engine will be manufactured using additive technologies. The production of the new power plants is carried out by CFM International, a cooperative of General Electric and the French company Safran - the same company that supplies half of the components for the Superjet engines.

And if you still have doubts about flying in 3D-printed airplanes, don't worry. Chances are that you are already familiar with them, and now you are reading this text in perfect health. The LEAP family engines entered service last year and, based on estimates from the International Air Transport Association (IATA), have delivered more than five million passengers to their destinations. Users include airlines such as AirAsia, EasyJet, Frontier, WOW air, SAS, Azul and Virgin America. They will also be used in the newest airliners Airbus A320neo, Boeing 737 MAX and COMAC C919. How many nozzles have already been printed? More than 30000 !!!

Why should nozzles be 3D printed? They shouldn't. Aviation has been doing fine without additive technologies for many years, but times are changing and the demands for efficiency and safety are growing. 3D printed nozzles are only 25% lighter and five times stronger and more reliable than their predecessors. Have a good flight!

Author: Studia3D aggregator

More articles from Studia3D aggregator