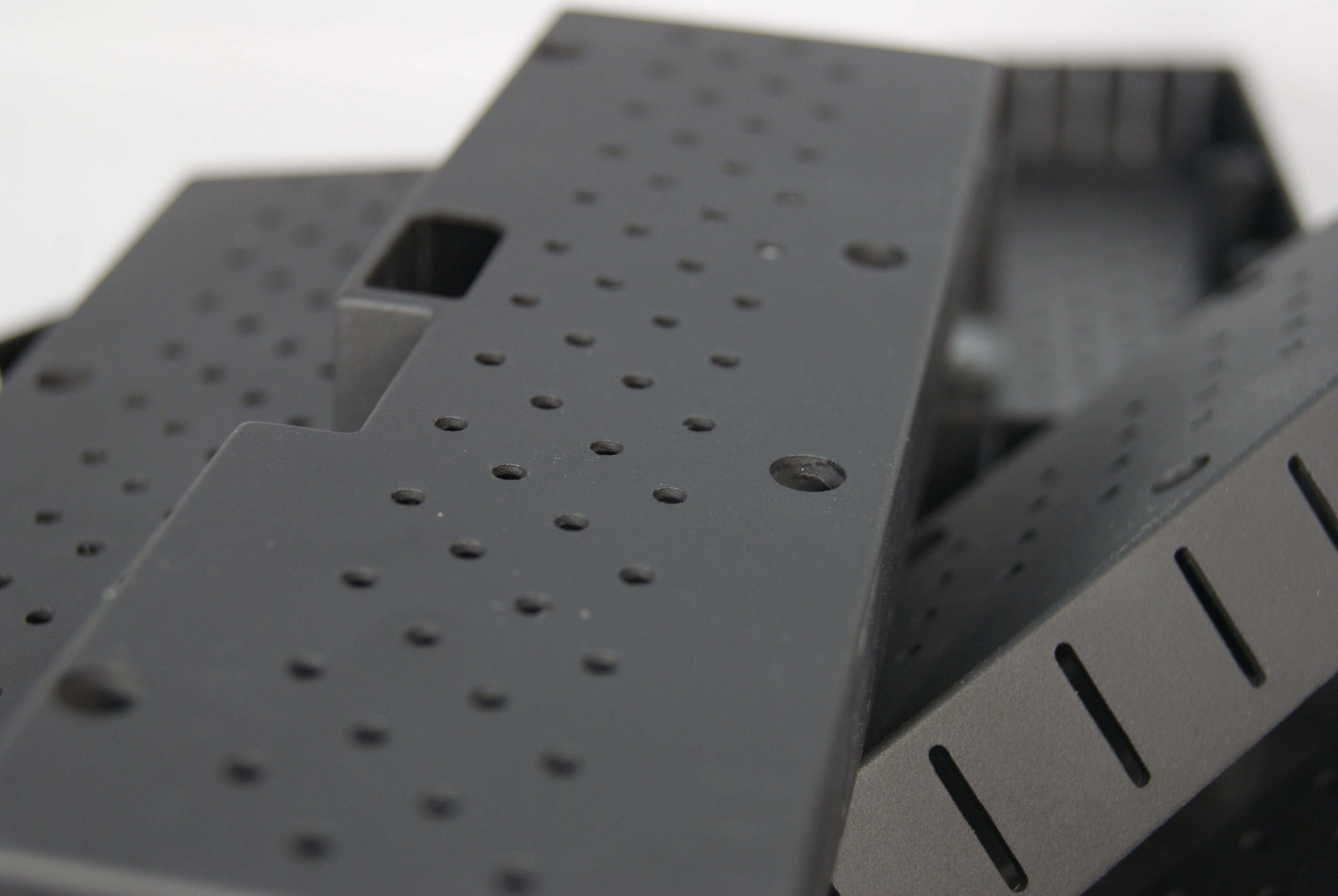

Our company has received an order to print cases for microelectronics.

Dimensional tolerances were very serious (this was especially true for the air ventilation holes, thanks to which the microboard did not overheat). We offered the customer to print a prototype from photopolymer, to make a "Master-model" from the printed part and then to cast the circulation from polyurethane into a silicone mold.

They decided to print with Visijet Cristal photopolymer, because it ideally matched the errors and tolerances specified in the Terms of Reference.

After printing, the model was qualitatively processed for removal of the silicone mold by our specialists.

The final batch was 10 pieces. They were cast immediately in black. The tolerances after casting did not exceed those specified in the technical specification.

The customer was completely satisfied.

Follow our news on the site and subscribe to our groups on VK, Instagram, Facebook and 3DToday.

Author: Studia3D aggregator

More articles from Studia3D aggregator