Team Studia3D, once again proved its professionalism in prototyping.

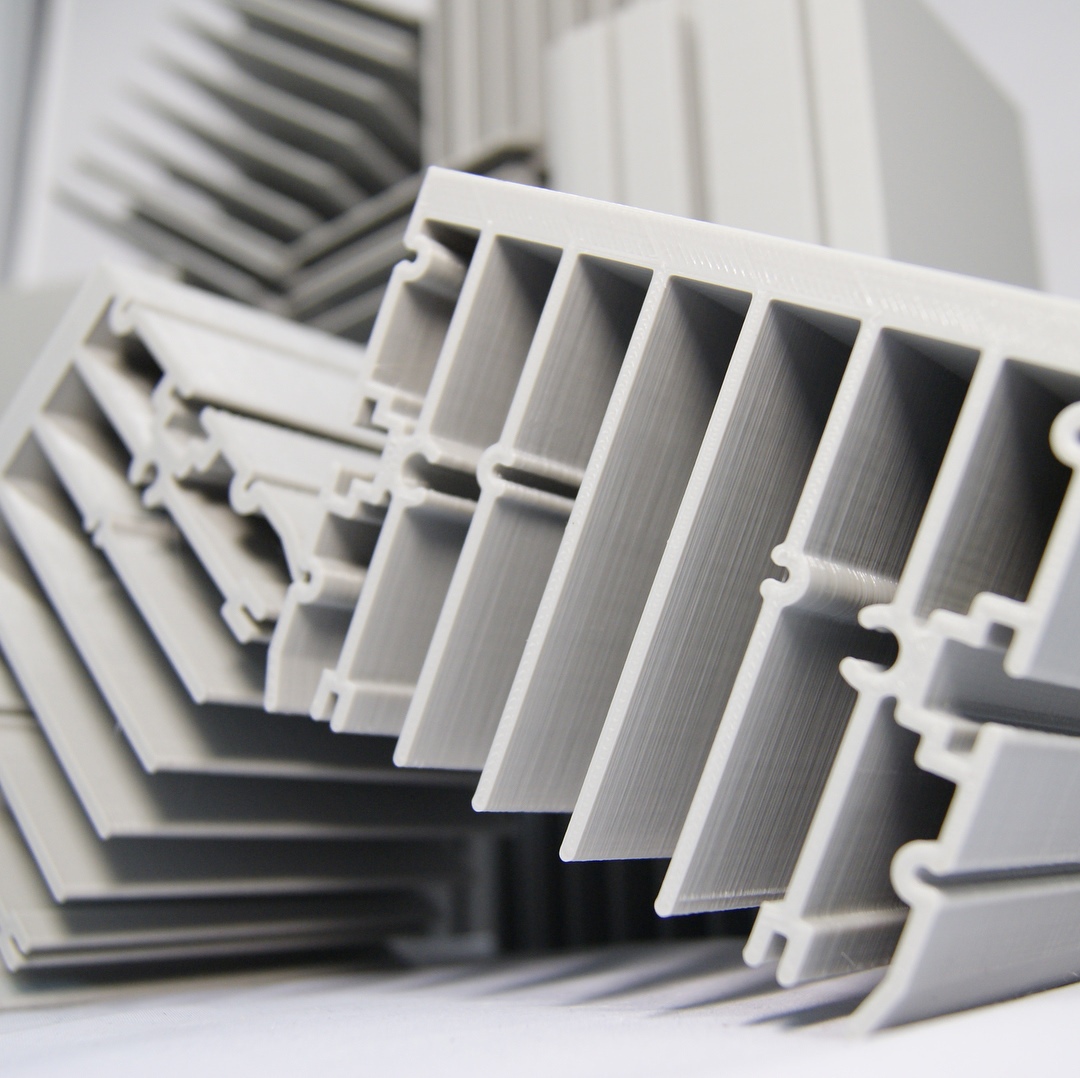

Our sphere allows you not only to partially make layouts, but allows you to create them on a turnkey basis. From simple elements to complex volumetric products.

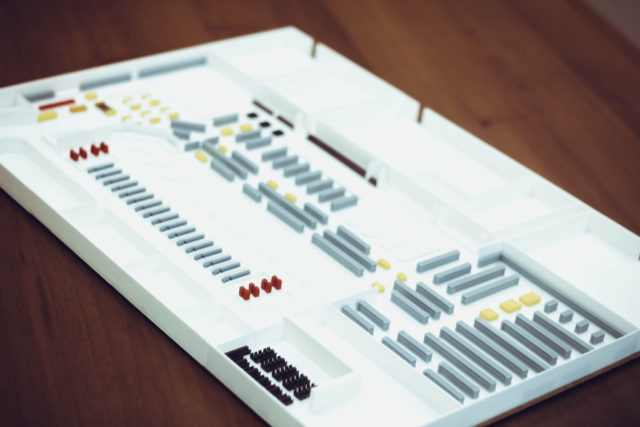

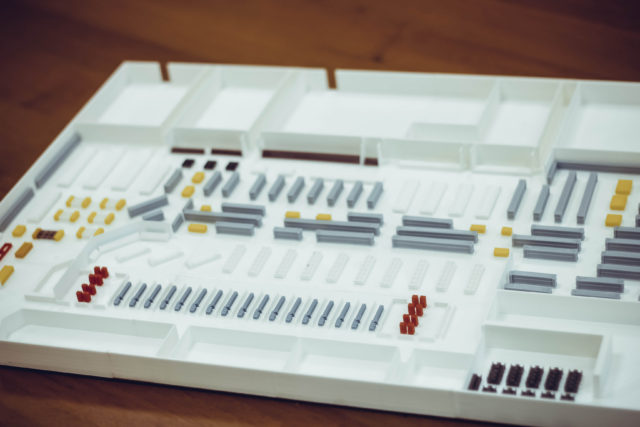

This time it was necessary to create a 3D model, a layout of a shopping center, then 3D printing. After the successful creation of a three-dimensional model, the technologists began to print the layout itself, printing was done in parts, as expected. Well, then the hardest part was: to glue all parts of the layout, and not just the body of the premises, but also the smallest details, conditional (refrigerators, racks, chairs, boxes, etc.). And since the deadlines were running out a little, the whole team Studia3D sat down at a round table, and glued the layout.

This mockup was printed on # picasopro250.

Author: Studia3D. Ru

More articles from Studia3D. Ru