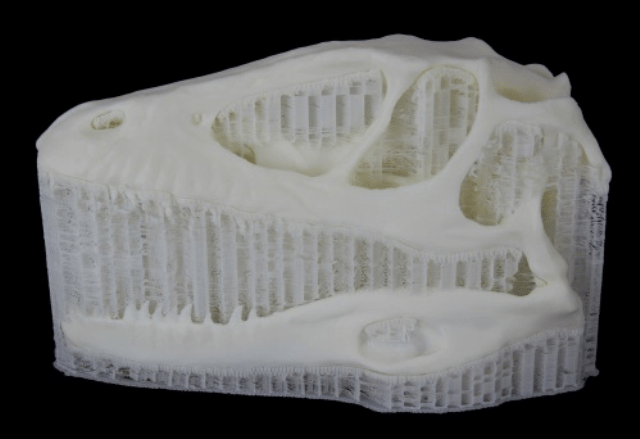

A very common situation - a part is not included in the maximum dimensions of the three-dimensional printing area, whatever one may say there. There is a solution! We cut the part into several parts, and after printing it can be glued, soldered, sewn, welded or simply docked. How to cut a 3D model into its constituent elements is described in this article. It should be remembered that with this method of 3D printing, it is necessary to take into account the accuracy of the comparison of the constituent parts. More details about accuracy can be found in the article: ACTUAL PRODUCT SIZE AFTER 3D PRINTING.

The methods below have been described based on the capabilities of NetFabb. This does not mean that you can only cut a model in NetFabb. Similar capabilities exist in many 3D modeling software. At the same time, the essence and approach remain the same.

Contents:

- Divide the object into components along the plane.

- Break the object into pieces with slots or snaps.

- Divide the object into its components with curly cuts.

- Video instruction.

1. Break into components along the plane.

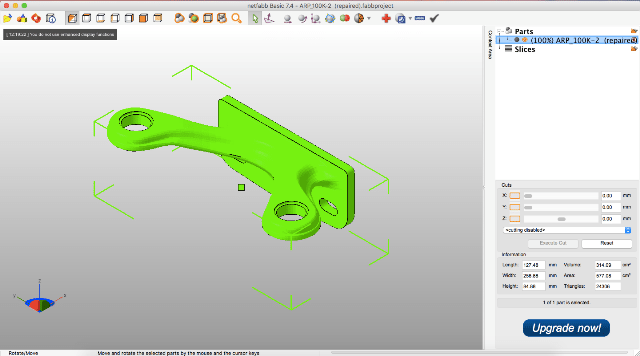

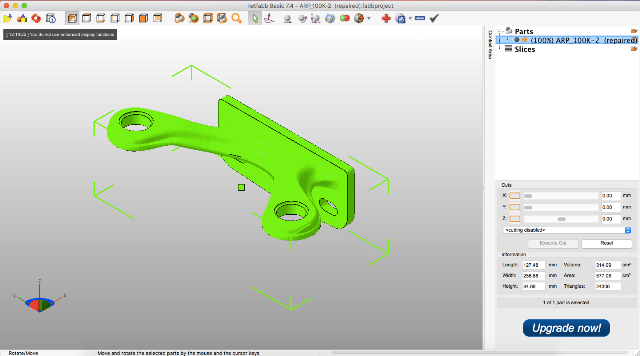

To split a part into several objects, let's turn to the NetFabb program. More information about the program and its capabilities can be found here.

After opening the model in the program, look for the “cuts” window. We start moving the sliders. As you can see, a stripe has appeared on our model. The so-called cutting line. Click “execute cut”.

The cutting plane appears. Here we can more accurately adjust the cutting line in terms of dimensions. Click “cut”.

As you can see, our part was split into two parts. Each part can be saved as a separate file and printed separately.

Let's consider another situation where we need additional latches or guides for correct positioning after breaking into components.

2. Break the object into pieces with slots or snaps.

Take Misha-Bear and mark the cutting line and click on the "Cuts" button.

But now, before the "cut" operation, we click on the "pin settings" button.

You should open a window where you will need to select what kind of alignment guides you need.

Cylindrical tapered groove:

Or, the so-called latch:

I selected the latch and defined all the parameters that I require. Please note that you can select the size, depth, overhang and other parameters for the connecting structures.

As you can see, our bear has additional fixators after splitting.

This path will help not only to correctly position the two parts relative to each other, but also fix one part to the other!

3. Divide the object into its components with curly cuts.

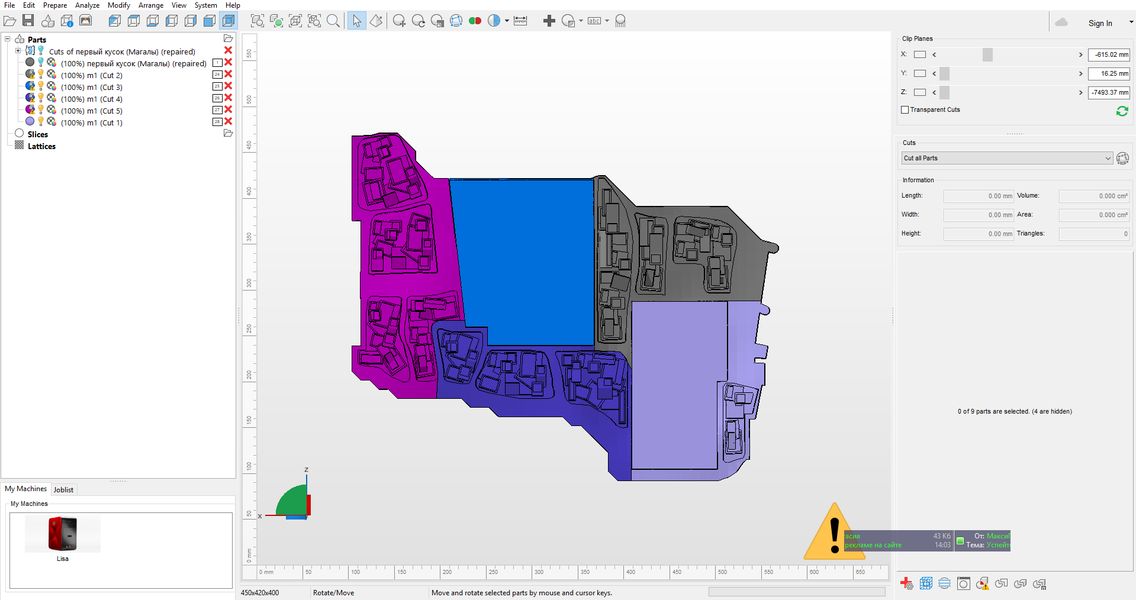

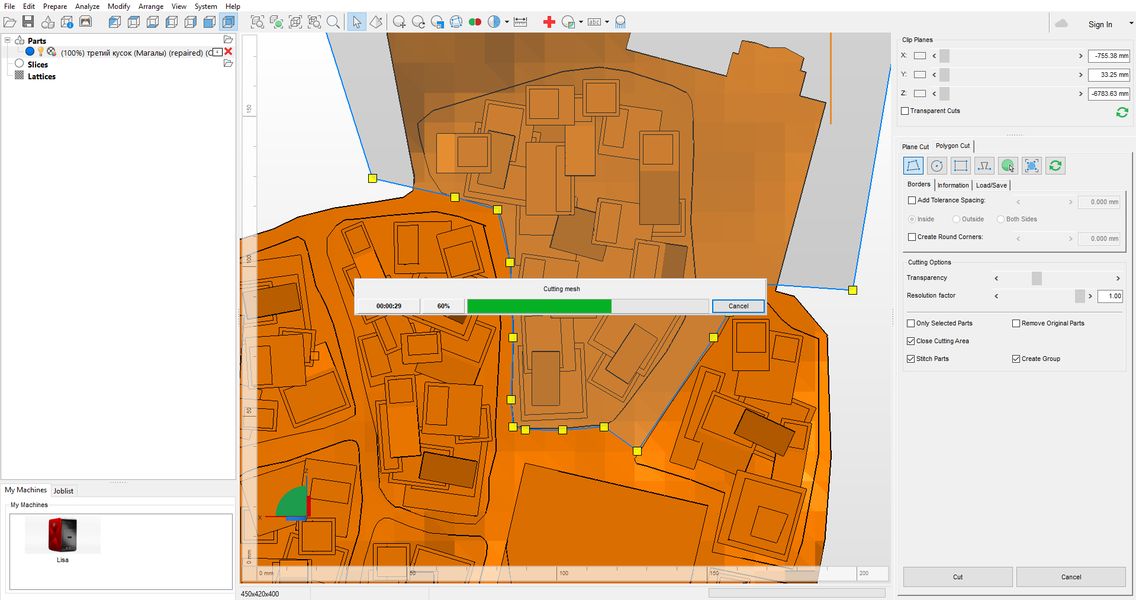

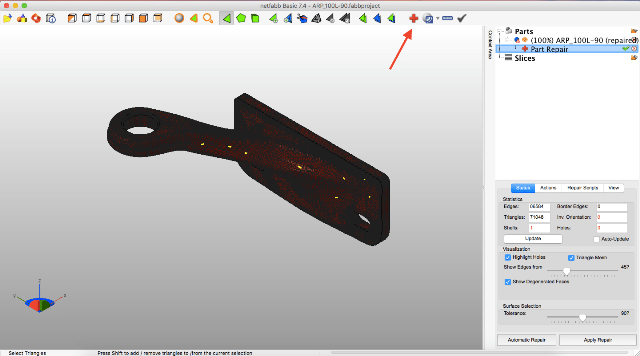

This section describes how to cut a 3D model with curly planes. Please note that it is possible to break an object into its components with curly cuts only if the model matches 3D printing requirements. If errors occur in the model while cutting, correct the model immediately after each cut. Before each subsequent cut, check the model for errors and correct them using the appropriate tools in Netfabb.

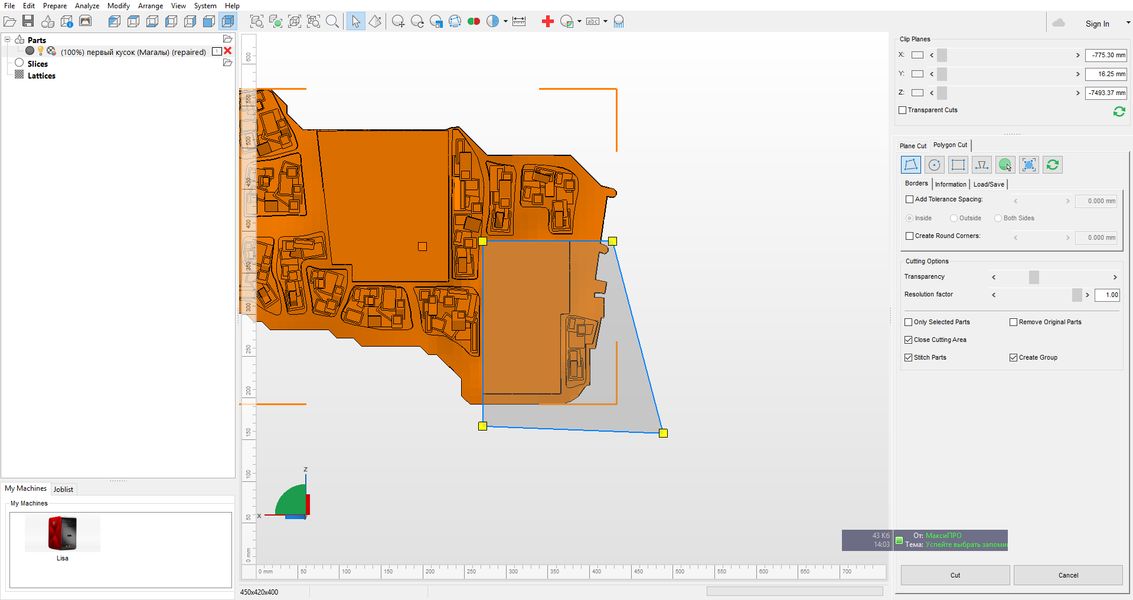

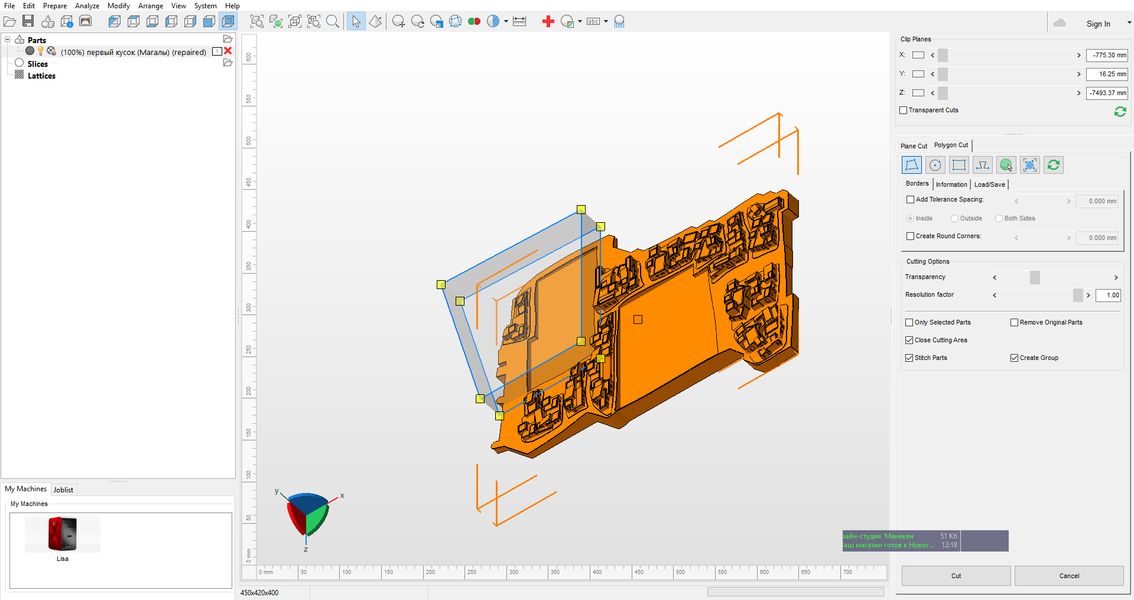

To be able to cut the part in the free space of the 3D model, you need to find the "Free Cut" button and click on it. Then it is necessary to mark the points sequentially in such a way as to describe the separated segment.

See below how it looks in run.

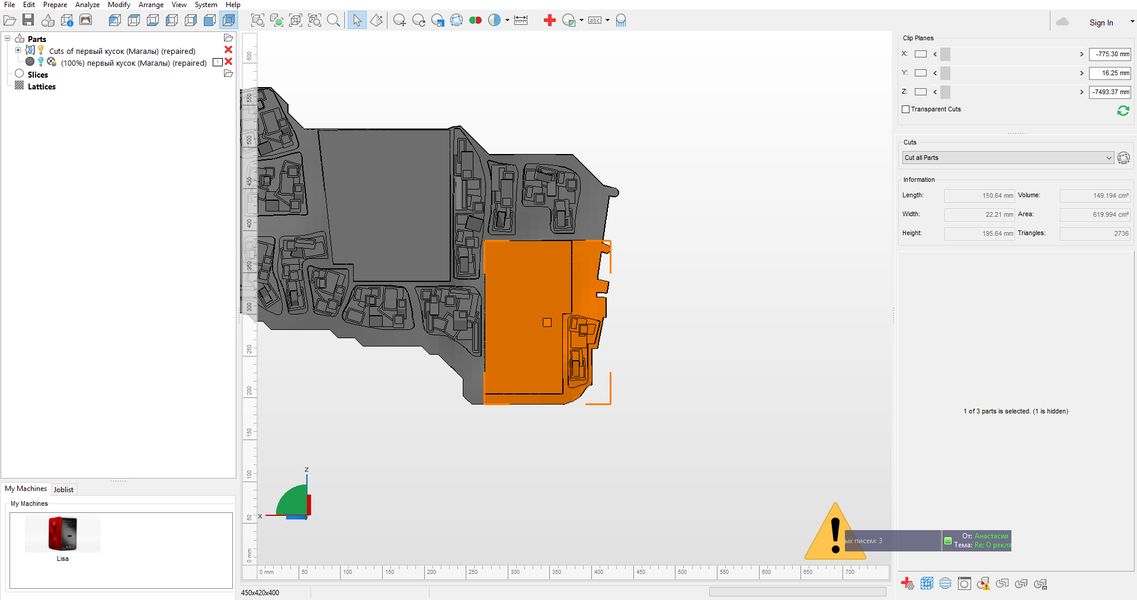

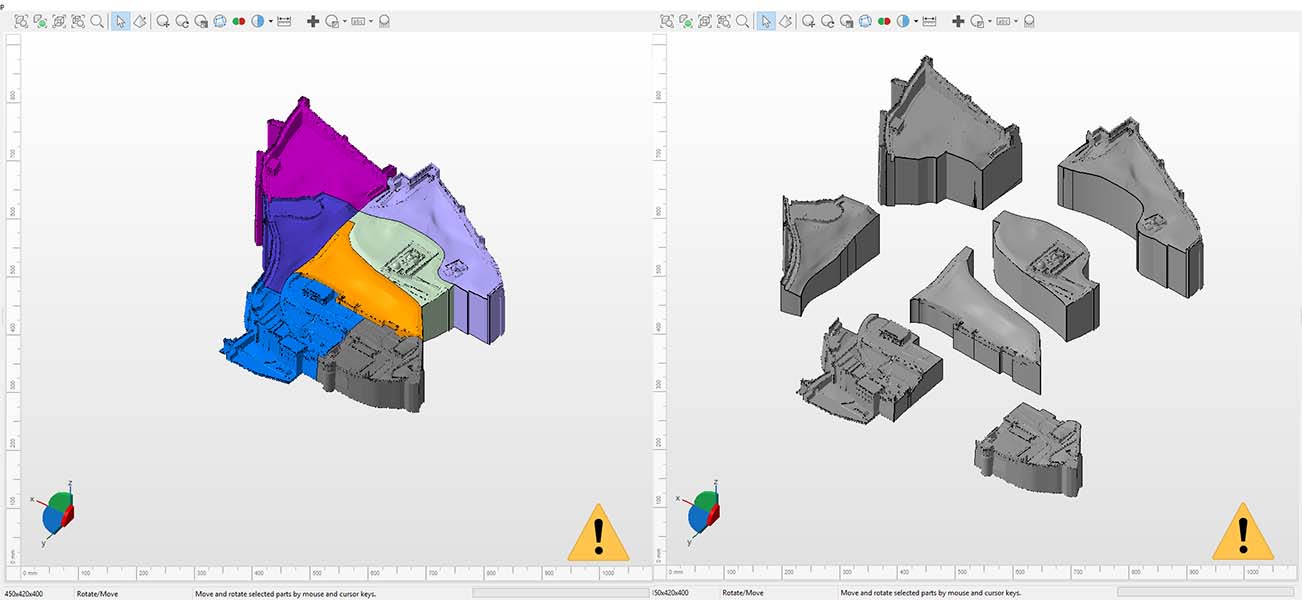

After the “Cut” command, you will get a separate segment and you can save it as a separate file.

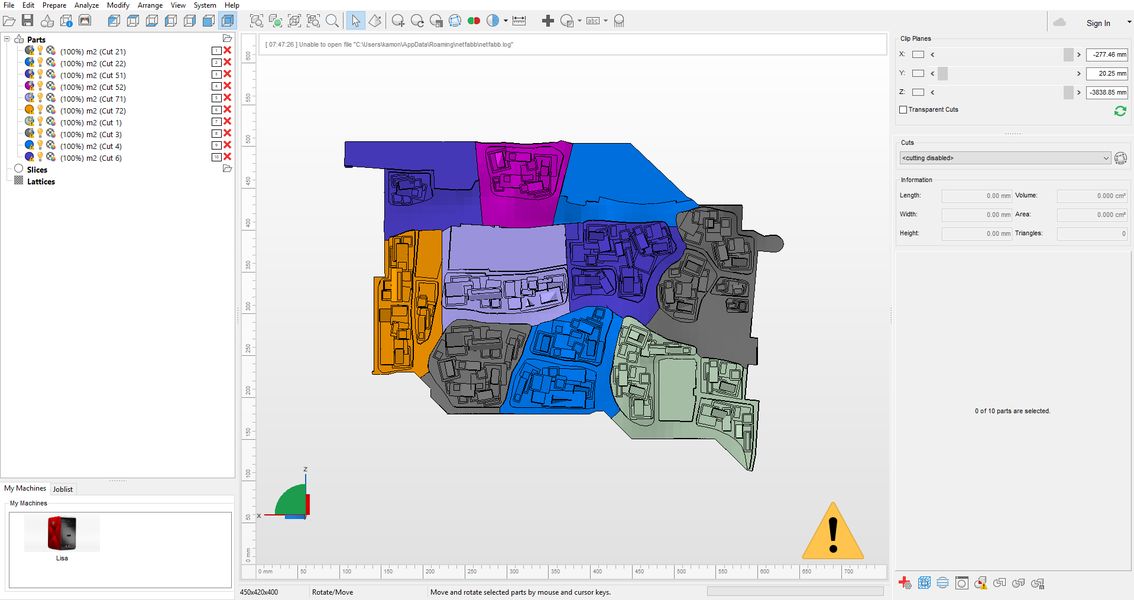

Thus, even if the 3D model does not fit into the 3D printing area, you can split it into many segments along the natural fold lines. And after 3D printing, the segments will be beautifully docked together.

Please note that cut lines can be as complex as you like.

And there can be as many cuts as you like.

Another example of such an iteration.

This approach will allow you to get even more quality in 3D printing.

4. Video instruction

Author: Studia3D. Ru

More articles from Studia3D. Ru