In this article, we will analyze the common errors that users of 3D printers that print using FDM technology face and how to fix them.

Select the problem you are having with your 3D printer.

Plastic leaks around the nozzle.

Plastic streaks near the thermal barrier.

Lack of filament supply from the nozzle.

The table or nozzle does not heat up.

The temperature sensor shows -14.

One or more axles do not move.

There is no or insufficient air flow from the fans.

When returning home, the printer beats at zero points.

The printer does not see the memory card.

Encoder not working.

There is no image on the screen.

Reboot printer during printing or does not turn on.

Instructions for action.

How to check the cable for integrity.

Replacing the control board.

How to clean the nozzle with a needle.

How to twist the nozzle and thermal barrier.

If you encounter problems that are not described in this article, please contact our specialists. You can order diagnostics and repair of your equipment.

Plastic leaks around the nozzle.

If drops of plastic appear on the model during printing and when removing casing Since the space around the nozzle is filled with plastic, it is necessary to screw the nozzle with a small force so that it does not touch the heating block at a distance of ~1 mm according to an example.

Plastic streaks near the thermal barrier.

If plastic drops appear on the model during printing and when the casing is removed, the space around the thermal barrier is filled with plastic, then it is necessary to screw the thermal barrier with a little force so that the nozzle does not touch the heating block at a distance of ~1 mm according to an example.

Lack of filament supply from the nozzle.

If the nozzle is heated to the required temperature, and the plastic is not pushed even by hand, then it is necessary clean the nozzle with a special needle by certain method. If the plastic goes by hand without problems, but the extruder still does not extrude it, then it is necessary check the cable stepper extruder motor for integrity and, if damage is found, replace the cable with a suitable or solder. Visually check the clamping mechanism for chips, cracks and, if any, replace with an identical one.

The table or nozzle does not heat up.

If the temperature on the screen corresponds to room temperature, but the temperature does not change when the heating command is given, then it is necessary to check heater cable and, if damaged, replace it with an identical or solder.

The temperature sensor shows -14.

If the temperature on the screen does not correspond to room temperature, then you need to check the thermistor cable and, if damaged, replace the temperature sensor with an identical one or solder.

One or more axles do not move.

If there is no movement when the command to move is given and the stepper motor does not perform rotational movements, then it is necessary check stepper motor cable and if it is damaged, then replace it with a suitable one. If there is no damage, this means that the control board itself burned out, and it replacement required. If it is clear that the stepper motors are rotating, but there are no movements, then it is necessary pull the appropriate toothed belt.

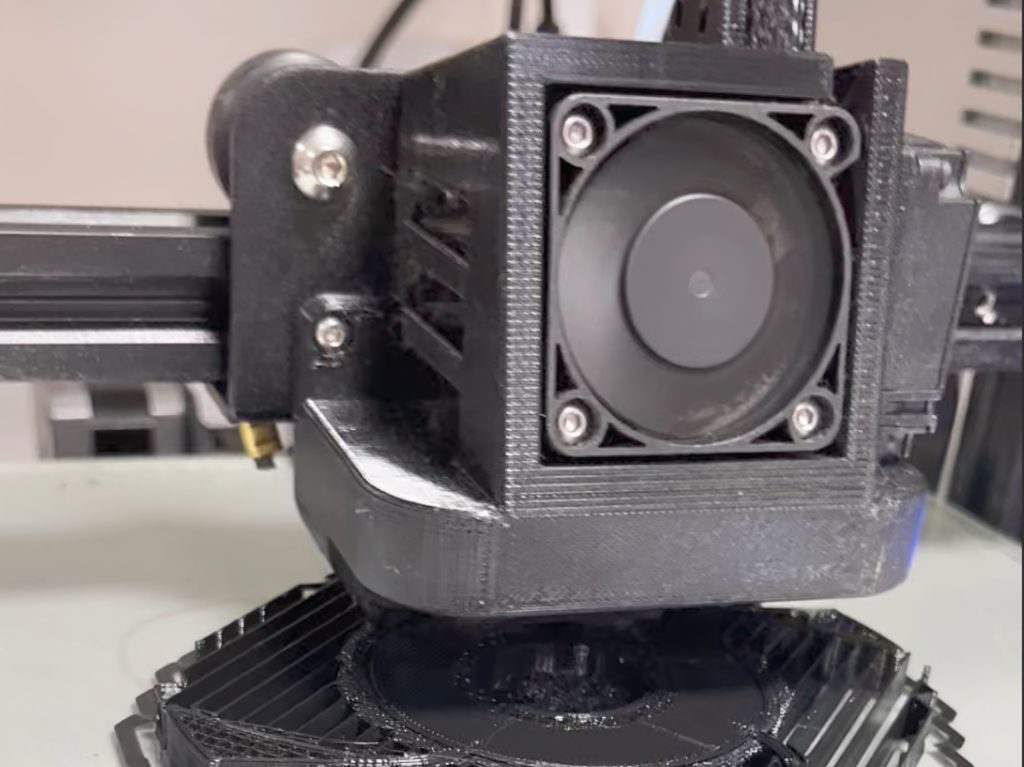

There is no or insufficient air flow from the fans.

If the propeller does not rotate or rotates too slowly, then it is necessary first of all to remove all accumulated debris near the blades with tweezers. If there is no change after this procedure, then check the cable and replace the cooler with wire in case of damage or solder.

When returning home, the printer beats at zero points.

If, when a command is given to return the printer to zero points at the end of the path, it continues to try to move and does not stop, then it is necessary check the cable and replace if damaged or solder. If, after checking, no damage was found, then it is necessary to replace the limit switch with a suitable one.

The printer does not see the memory card.

If the printer does not see the files recorded on the memory card, then you need to check it using a computer, in the event that the PC sees the drive format it, the lack of reaction from the PC to the card indicates its breakdown. If, after performing the above steps, nothing has changed and the printer is still unable to read the memory card, this means that The control board is damaged and needs to be replaced..

Encoder not working.

If, when trying to interact with the menu, the encoder does not perceive actions or perceives them incorrectly, then it is necessary check the cablegoing to it, and in case of damage, replace or solder. In the absence of improvements in the operation of the encoder, it is necessary to replace the screen with it with an identical one. In the event that the encoder is still in an inoperative state, then this means that the control board is damaged and needs to be replaced.

There is no image on the screen.

If there is no image on the screen, then check the cable going to it and in case of damage, replace or solder. If there is no image, replace the screen with an identical one. In the event that after the above actions the image is still missing, then this means that The control board is damaged and needs to be replaced..

Reboot printer during printing or does not turn on.

If the printer restarts while printing, the first thing to check is the voltage of the power supply. For this you need: put the multimeter in DC voltage measurement mode, touch the pad with + with one probe, with the other with - and compare the readings with those indicated on the power supply. If there is a difference in readings, the unit must be replaced, otherwise it is necessary control board replacement.

How to check the cable for integrity.

First of all, you need to visually verify that there are no creases, cuts, melting on the surface of the cable. If there is no visual damage, then it is necessary put the multimeter into dialing mode, and using this mode, check each individual wire in the cable.

Replacing the control board.

Before proceeding with the replacement, it is necessary to completely turn off the power to the printer, and it is also extremely important to remember the exact location of each wire connection. In the process of disconnecting the wires, it is forbidden to press, bend or apply other physical loads on the board. During the connection process, the new board must be on a flat, non-conductive surface.

How to clean the nozzle with a needle.

Heat the nozzle to 220-240, take a needle corresponding to the diameter of the nozzle, insert it into the channel and move the needle, try to push the plastic by hand, repeat until the filament comes out in an even stream.

An example of how the nozzle should be twisted.

It is generally accepted that the nozzle is fully screwed into the heating block, as shown on the left side of the image below. However there are caseswhen the right example in the image is correct. In addition, we pay attention to screwing the thermal barrier into the heating block. Thermal barrier situation similar nozzles Please note that when screwing the nozzle and thermal barrier, the least amount of force must be applied. Usually these elements are made of soft materials and can be damaged due to excessive force. They should spin smoothly and neatly. The thread should not heel and resist.

If you encounter problems that are not described in this article, please contact our specialists. You can order diagnostics and repair of your equipment.

Author: Studia3D aggregator

More articles from Studia3D aggregator